Description

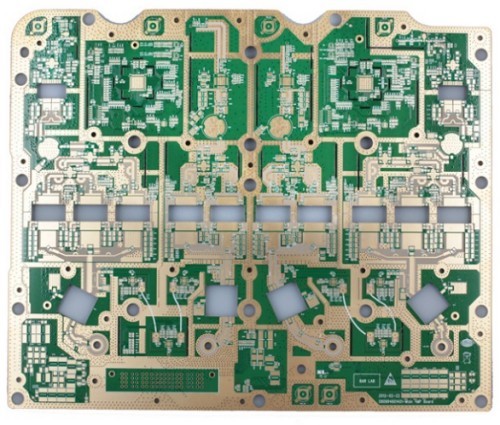

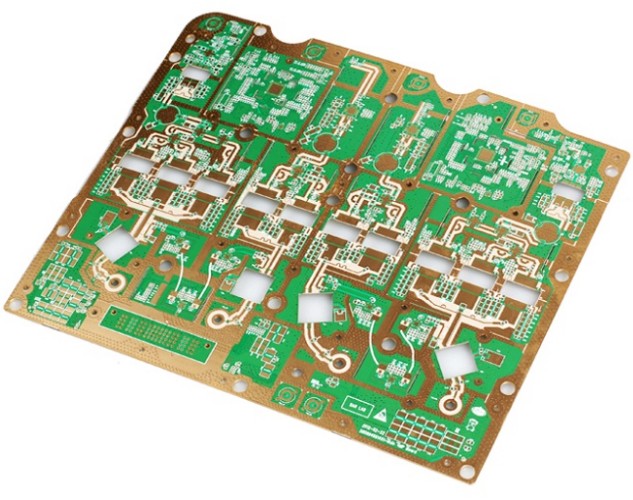

Rogers taconic FR-4 pcb

Number of floors: 4

Plate thickness: 2.0 ± 0.14mm

Plate used:Taconic+FR4

size:210mm*280mm

Minimum hole diameter: 0.3mm

Surface treatment:immersion gold

Minimum trace width/distance: 0.18mm/0.2mm

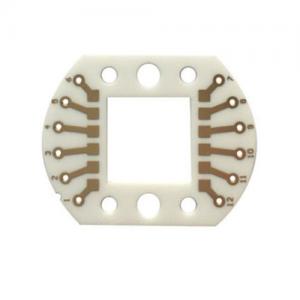

Process characteristics: high-frequency materials, Taconic+FR4 Shengyi mixed lamination

Application field: communication

Characteristics of High frequency mixed board: stepped blind slot design

Taconic and FR-4 are two common types of printed circuit board (PCB) materials. Their hybrid laminates have certain advantages in some high-frequency and high-speed applications. The following are some characteristics and application scenarios of Taconic and FR-4 hybrid laminates:

- High-frequency performance: Taconic materials usually have a lower dielectric constant and loss factor, which can provide better high-frequency signal transmission performance. Mixed use with FR-4 can balance high-frequency performance and cost to a certain extent.

- High-speed digital signals: For high-speed digital circuits, the hybrid laminate can reduce the delay and distortion of signal transmission and improve signal integrity.

- Wireless communication: In wireless communication devices such as antennas and RF modules, the hybrid laminate can provide better RF performance and anti-interference ability.

- Satellite communication: Satellite communication systems have high requirements for high-frequency performance and reliability, and Taconic and FR-4 hybrid laminates can be used in the manufacture of satellite communication equipment.

- Medical equipment: Some medical equipment, such as high-frequency therapy devices and medical imaging equipment, may also use hybrid laminates to meet specific performance requirements.

It should be noted that the specific application scenarios and performance requirements will vary depending on product design and engineering requirements. When choosing Taconic and FR-4 hybrid laminates, it is recommended to consider the following factors:

- High-frequency performance requirements: Determine the required dielectric constant and loss factor according to the specific working frequency and signal transmission requirements.

- Cost and manufacturability: Taconic materials are usually more expensive than FR-4, so a trade-off between performance and cost is required. At the same time, consider the processing capabilities and process requirements of the manufacturer.

- Thermal stability: Some applications may have requirements for the thermal stability of the circuit board, ensuring that the hybrid laminate can maintain stable performance in the working environment.

- Signal integrity: For high-speed digital signals, issues such as impedance control, crosstalk, and reflection of the hybrid laminate need to be concerned to ensure good signal integrity.

It is best to cooperate with professional PCB manufacturers or suppliers, and they can provide more detailed suggestions and select the appropriate hybrid laminate material according to your specific needs. In addition, relevant technical specifications and data manuals can also be referred to for more accurate performance information and design guidance.