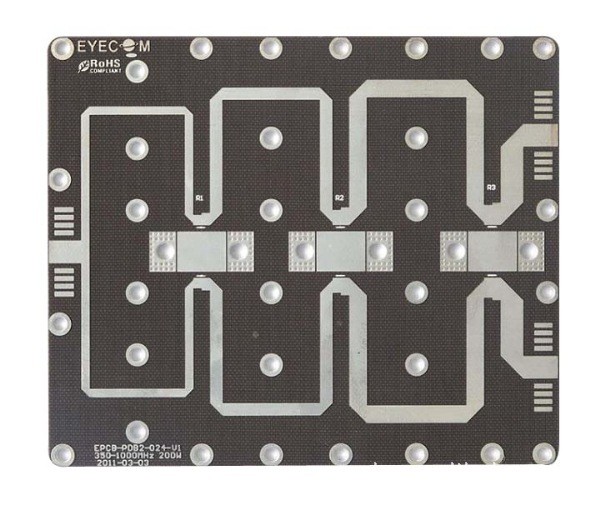

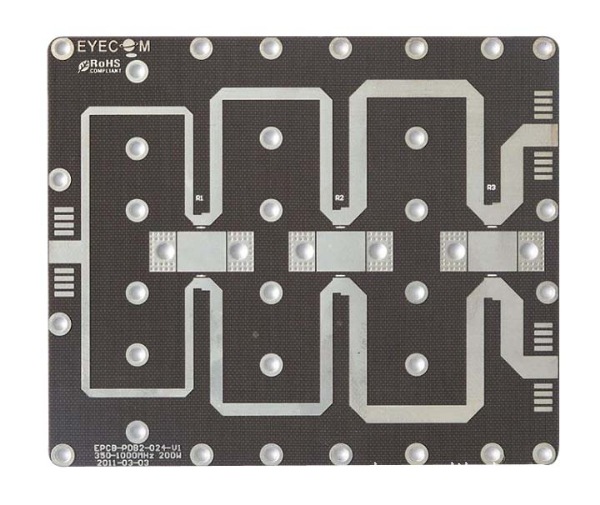

Description

nelco pcb

Number of floors: 2

Plate thickness: 0.8 ± 0.1mm

Plate used:nelco nx9240

Dielectric constant: 2.33

Minimum hole diameter: 0.2mm

Surface treatment:immersion silver

black soldermask

Minimum trace width/distance: 0.2mm/0.2mm

Process characteristics: high-frequency materials,nelco

Nelco PCB refers to the printed circuit board (PCB) made of Nelco laminate. Nelco laminate is a high-frequency and high-speed PCB material under the American AGC Corporation, which has characteristics such as low loss and high reliability, and is suitable for high-frequency application scenarios such as millimeter waves. The following are some common Nelco PCB materials:

- TLY-5Z: A low-loss PTFE material containing fiberglass cloth and ceramic filler, with a relatively low expansion coefficient in the Z-axis direction, which can improve the long-term reliability of metallized vias.

- NF-30: A PTFE material without fiberglass cloth. While ensuring extremely low dielectric loss, it can effectively avoid the potential CAF risk brought by fiberglass and enhance the consistency of electrical properties in all directions of the material.

- TSM-DS3: A low-loss PTFE material containing fiberglass cloth and ceramic filler, with excellent dimensional stability, and can be used with fastRise to fabricate high multi-layer circuit boards.

- Meteorwave series: A PPO/PPE resin system material, with excellent PCB processability. Its dielectric loss is between that of PTFE and hydrocarbon resin materials, and the price is relatively low.

In practical applications, when choosing Nelco PCB materials, factors such as the specific application scenario, working frequency, performance requirements, and cost need to be considered. At the same time, relevant design and manufacturing specifications need to be followed to ensure the quality and reliability of the PCB.