What is ICT?

ICT test is very common in SMT chip processing factories, but the general public do not understand what the use of this test, the following is an introduction to what the ICT test is.

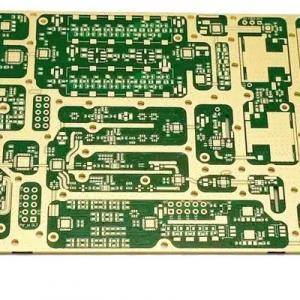

ICT automatic in-line tester

What is ICT?

ICT is the English (In-Circuit-Test), the Chinese direct translation is automatic online testing, but the industry should be more accurately called circuit testing.ICT is mainly used for electrical testing of circuit boards (PCBAs) and can be thought of as an advanced multimeter, which can be used to check the electrical properties of all parts on the board and the soldering for open/short circuit problems without removing the electronic parts from the board.

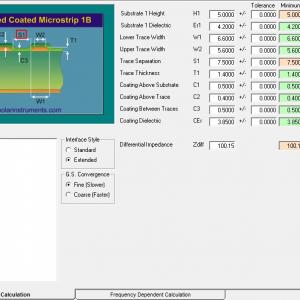

The principle of ICT testing

ICT testing is based on the use of a bed of needles to connect the test points on the circuit board to achieve the test purpose. The ICT must be placed on the contact points of all components to measure resistance, capacitance and voltage.What are the main ICT tests?

- 1. short circuits, wrong parts, missing parts, standing stones, bridges, reverse polarity, etc.

- 2. Measurement of resistors, capacitors, inductors, diodes, voltage regulators, relays, ICs, connectors and other components.

- 3. Electrical function tests.

- 4. Testing the function of active parts.

Advantages of ICT testing of pcba boards.

1. Fast and short testing timePCBA does not need to power on the machine can do L / C / R / D test, can effectively reduce the test waiting time, but also to reduce the short circuit caused by the board burn accident

2. Excellent retestability

Controlled by the computer program, it greatly reduces the risk of misjudgement and missed tests, reducing the trouble of the production line.

3. Significant reduction in product maintenance costs

The operator is responsible for the maintenance of the product, effectively reducing labour costs. ICT can tell which part is defective through the computer programme.

4. Improved product quality

As long as there are enough test points, ICT can measure all the circuits and parts on the circuit board, which can improve the quality of the product.

Disadvantages of ICT testing:

- 1. ICT equipment and fixtures are generally more expensive, especially pneumatic steel fixtures, which are more suitable for mass-produced products.

- 2. When using ICT testing, additional test points need to be designed on the circuit board for connection to the needle bed. This reduces the use of circuit board wiring.

- 3. The needle bed requires regular maintenance and the probes need to be replaced regularly to ensure that they and the probes are functioning properly.