Illustration: How to identify common SMT polarity components

Polarity components in the entire PCBA processing process requires special attention, because the direction of the component error will lead to bulk accidents and the failure of the entire PCBA board, so engineering and production staff to understand the SMT polarity components is extremely important.I. Definition of polarity

Polarity refers to the positive and negative polarity or the first pin of the component and the PCB (printed circuit board) on the positive and negative polarity or the first pin in the same direction, if the component does not match the direction on the PCB, it is called reverse bad.

II, the polarity identification method

1, chip resistor (Resistor) no polarity

2、Capacitor

2.1 Ceramic capacitor without polarity

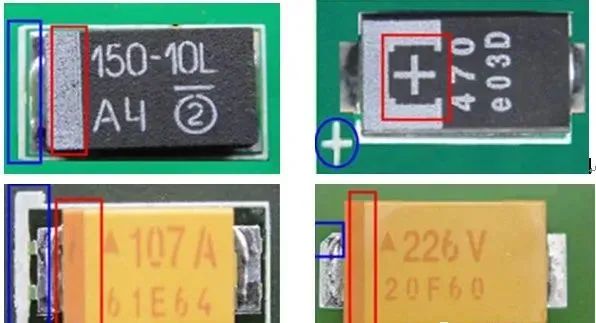

2.2 Tantalum capacitor has polarity. PCB board and device positive marking: 1) ribbon marking; 2) " " sign marking; 3) bevel marking.

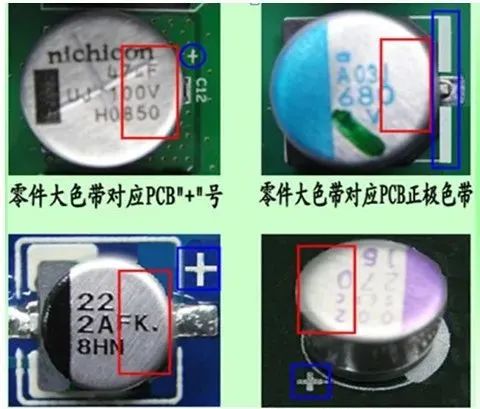

2.3 Aluminium electrolytic capacitors have polarity. Part marking: colour band for negative; PCB board marking: colour band or " " sign for positive.

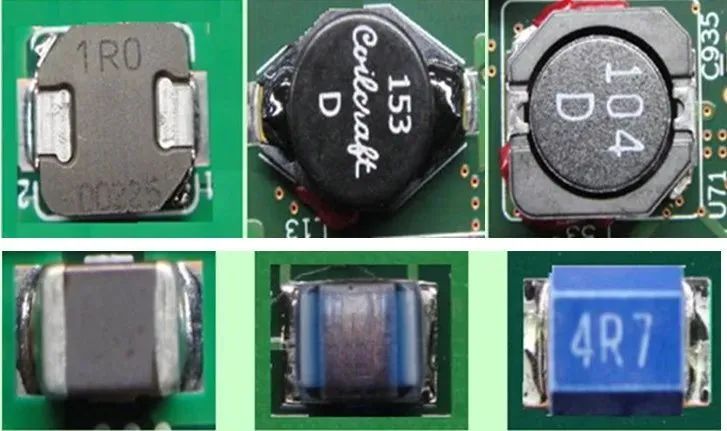

3、Inductors (Inductor)

3.1 Two solder end packages such as chip coils have no polarity requirement

3.2 Multi-pin inductors have polarity requirements. Part markings: dot/"1" for polarity; PCB markings: dot/circle/"*" for polarity.

4, Light Emitting Diode (Light Emitting Diode)

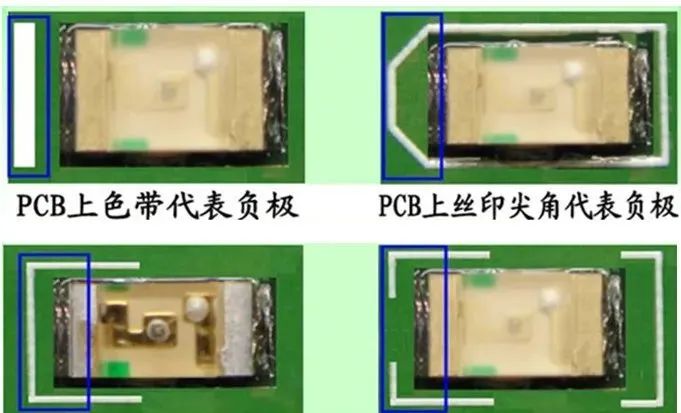

4.1 SMT surface-mounted LEDs have polarity. Parts negative labeling: green for negative; PCB negative labeling: 1) vertical bar on behalf of; 2) ribbon on behalf of; 3) silk-screened sharp corner on behalf of; 4) silk-screened "匚" box on behalf of.

5, diode (Diode)

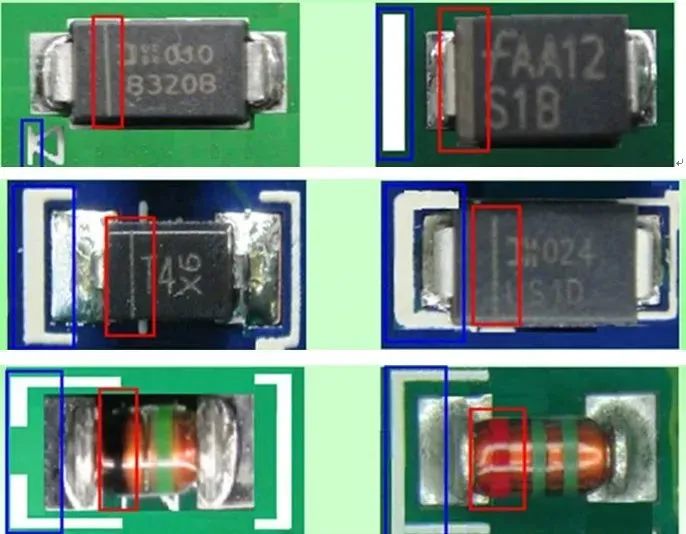

5.1 SMT table sticker two-terminal diode has polarity. Parts negative marking: 1) ribbon, 2) groove, 3) colour marking (glass body); PCB negative marking: 1) vertical bar marking, 2) ribbon marking, 3) silk-screened sharp corner marking, 4) "匚" box marking.

6, integrated circuit (Integrated Circuit)

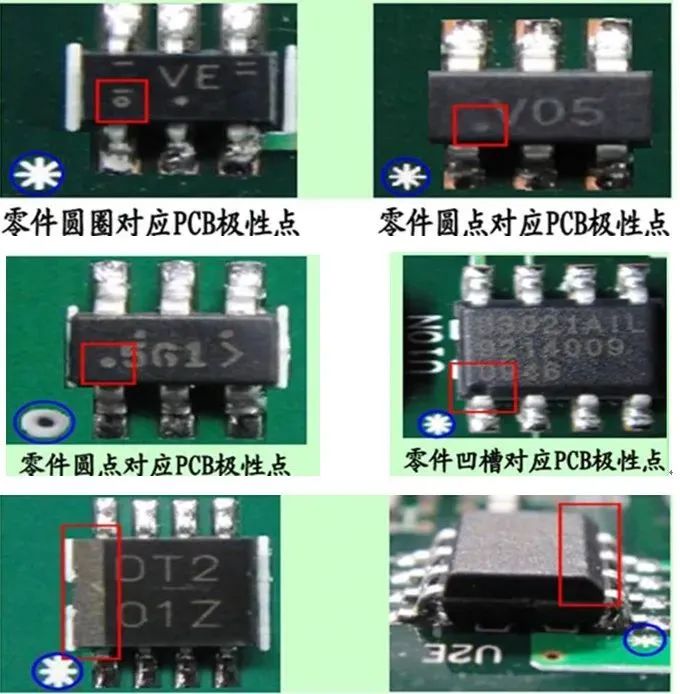

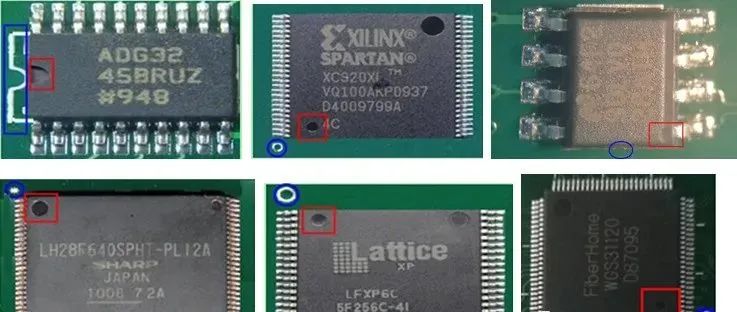

6.1 SOIC type packages are polarised. The polarity is indicated by 1) the ribbon, 2) the symbol, 3) the dots and grooves, and 4) the beveled edges.

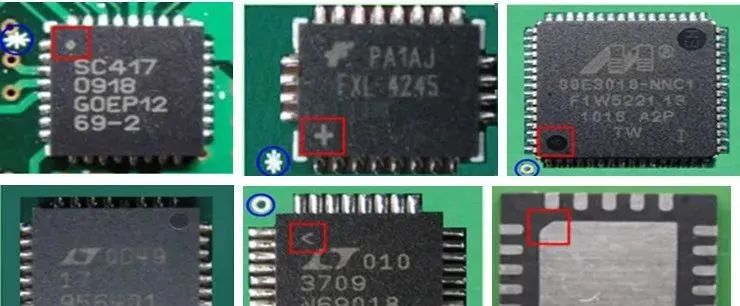

6.2 SOP or QFP type packages are polarised. The polarity is indicated by 1) the notch/notch, 2) the difference (size/shape) between one of the dots and the other two/three dots.

6.3 QFN type packages have polarity. Polarity marking: 1) one dot is different from the other two (size/shape), 2) bevelled edge marking, 3) symbol marking (horizontal bar/" " sign/dot).

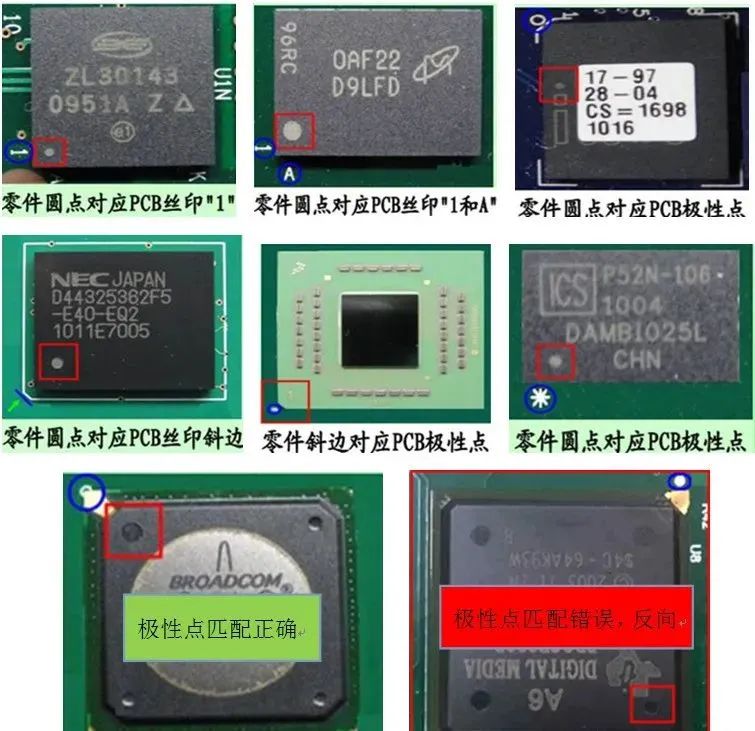

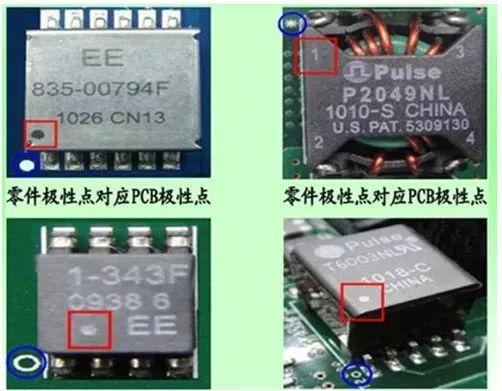

7、Grid arrangement of spherical foot chips (Ball Grid Array)

7.1 Part polarity: dots / notches / dots / circles; PCB polarity: circles / dots / letters "1 or A" / bevelled marks. The part polarity points correspond to the polarity points on the PCB.