Description

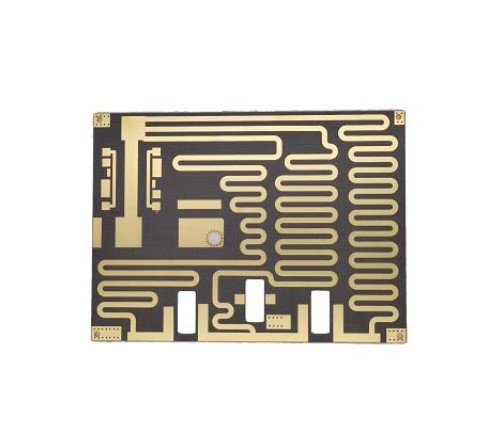

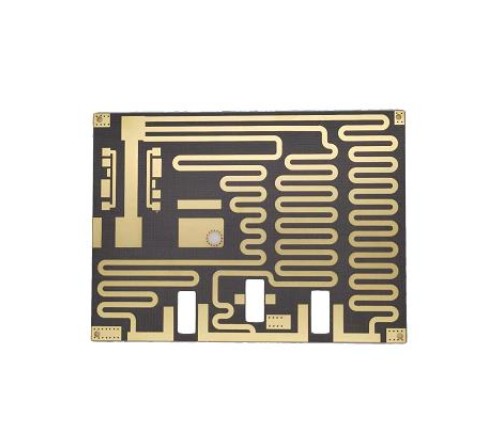

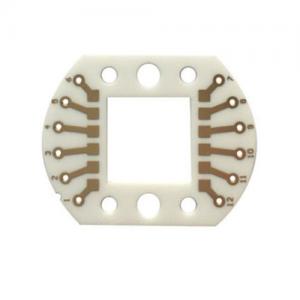

Teflon PTFE F4BM-220 PCB,

Number of floors 2,

Plate thickness 1.6 ± 0.16mm,

Dielectric thickness 1.5mm

Plate used Teflon PTFE F4BM-220,

Dielectric constant 2.2

Thermal conductivity:0.8w/m.k

Minimum hole diameter 0.3mm

Surface treatment plated gold,

Minimum trace width/distance 0.2mm/0.2mm,

Process characteristics high-frequency Teflon PTFE F4BM-220 materials

Teflon PCB is a kind of high-frequency PCB and has extremely excellent performance in PCB prototyping, especially suitable for applications in the fields of radar, high-frequency communication equipment, wireless electrical equipment, etc.

In addition to these, Teflon PCB can also be applied in the following fields:

- Electronic field: It can be applied to electronic devices such as power amplifiers and low-noise amplifiers.

- Medical field: Teflon has outstanding and excellent comprehensive performance, high temperature resistance, corrosion resistance, non-stick, self-lubrication, excellent dielectric properties and very low friction coefficient, so it also has certain applications in the medical field.

- Chemical field: Teflon materials are widely used in industries such as atomic energy, national defense, aerospace, electronics, electrical, chemical, machinery, instrumentation, architecture, textile, metal surface treatment, pharmaceutical, medical, food, metallurgical smelting, etc. as high and low temperature resistant materials, insulation materials, anti-stick coatings, etc.

Teflon PTFE F4BM-220 PCB is a kind of printed circuit board (PCB) made of polytetrafluoroethylene (PTFE) material. PTFE has excellent chemical stability, corrosion resistance, high lubrication non-adhesiveness, electrical insulation and good anti-aging durability, and can work continuously at temperatures from -100 to +150 °C. This kind of PCB is usually used in high-frequency and microwave applications, such as satellite communication, navigation, radar, antennas, etc.

In the use of PTFE PCB, the following issues need to be noted:

- Temperature limitations: The operating temperature range of PTFE is -100 to +150 °C. During use, it should be avoided to exceed its upper temperature limit, otherwise it may lead to material decomposition or performance degradation.

- Cold flow property: PTFE has the "cold flow property". Under long-term continuous loading, plastic deformation may occur. Therefore, this factor needs to be considered in design and use, such as avoiding excessive compression or using appropriate support structures.

- Poor thermal conductivity: The thermal conductivity coefficient of PTFE is low, which is not conducive to heat dissipation. Therefore, heat dissipation issues need to be considered in the design, such as adding heat sinks or adopting other heat dissipation measures.

- Large linear expansion coefficient: The linear expansion coefficient of PTFE is relatively large, and there will be large dimensional changes when the temperature changes. Therefore, this factor needs to be considered in design and use, such as reserving sufficient gaps or adopting compensation measures.

- Great processing difficulty: The melt viscosity of PTFE is high and does not flow at high temperatures, so it is more difficult to process and requires special processing methods, such as sintering molding.

- High cost: The price of PTFE is relatively high, so the cost factor needs to be considered when using it, such as trying to choose the appropriate thickness and size on the premise of meeting the performance requirements.

When using PTFE PCB, it is recommended to follow the manufacturer's suggestions and specifications to ensure its performance and reliability.