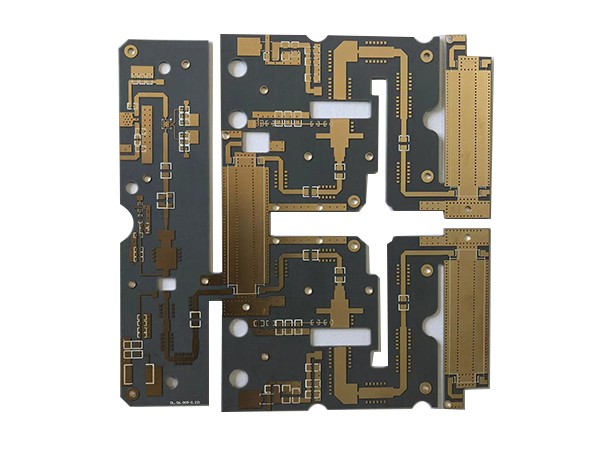

Description

board thick:1.575mm

Number of floors: 2

Dielectric constant: 2.2

Dielectric loss factor: 0.0004(1 MHz),0.0009(10 GHz)

Plate thickness:1.524mm

Plate used:Rogers RT/duroid 5880

TD:500

Thermal conductivity:0.2w/m.k

Minimum hole diameter: 0.2mm

Surface treatment:ENEPIG

Minimum trace width/distance: 0.2mm/0.2mm

Process characteristics: high-frequency materials,Rogers RT/duroid 5880

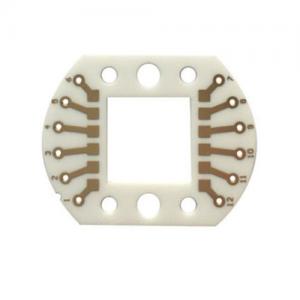

RT/duroid 5880 is a high-frequency circuit board material launched by Rogers Corporation, which belongs to polytetrafluoroethylene fiberglass reinforced material. It has the following characteristics and advantages:

- Extremely low dielectric constant: Measured under the 10 GHz IPC-TM 2.5.5.5 standard, its dielectric constant is 2.20 ± 0.02, which can effectively reduce the dispersion and loss of signal transmission.

- Extremely low dielectric loss: Measured under the same standard, its dielectric loss factor is only 0.0009, which is suitable for high-frequency and wide-band applications.

- High-frequency support: The maximum supported frequency can reach the Ku band or even higher, which can meet the high-frequency requirements such as millimeter wave applications.

- Low moisture absorption rate: The moisture absorption rate is only 0.02%, making it have good stability and reliability in high humidity environments.

- Easy to process: It can be easily cut into the required shape to adapt to the requirements of various cavity structures.

- Chemical corrosion resistance: It can resist the erosion of all solutions and reagents used in the etching and plated through-hole processes.

- Good electrical performance: It has isotropy, and the electrical performance changes very little with the frequency.

Based on the above characteristics, the RT/duroid 5880 board is mainly used in the following fields:

- Commercial aviation telephone circuits

- Microstrip and stripline circuits

- Millimeter wave applications

- Military radar systems

- Missile guidance systems

- Point-to-point digital radio antennas.