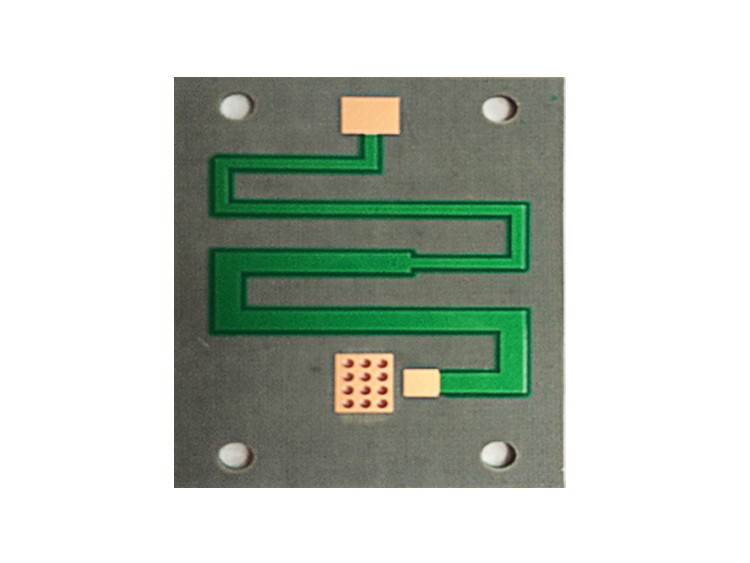

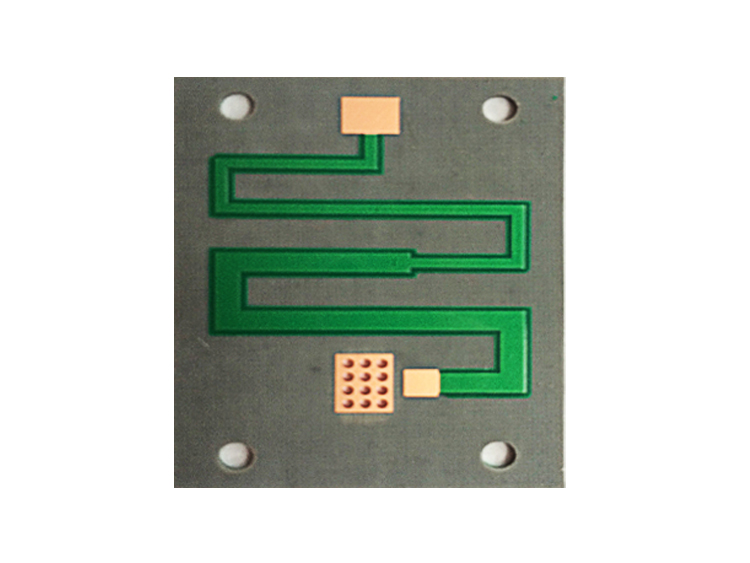

Description

Teflon pcb

Number of floors: 2

Plate thickness: 0.8 ± 0.1mm

Plate used: teflon,PTFE,f4B

Dielectric constant: 2.65

Dielectric loss factor: 0.0037

Minimum hole diameter: 0.3mm

Surface treatment:plated gold

Minimum trace width/distance: 0.2mm/0.2mm

Process characteristics: high-frequency materials,teflon,F4B,PTFE

Teflon F4B PCB.

Teflon F4B PCB is a kind of high-frequency circuit board, which has excellent high-frequency performance and stable electrical performance, and is widely used in high-frequency fields such as wireless communication, satellite navigation, and radar. Here are some common questions and answers about Teflon F4B PCB:

- What is Teflon F4B PCB?: Teflon F4B PCB refers to a printed circuit board using Teflon (polytetrafluoroethylene) material as the substrate. Teflon has characteristics such as a low dielectric constant, a low loss factor, and high heat resistance, which can meet the requirements of high-frequency signal transmission.

- What are the advantages of Teflon F4B PCB?: Teflon F4B PCB has the following advantages:

- Good high-frequency performance: It can effectively reduce the loss and distortion in signal transmission;

- Stable electrical performance: The electrical performance remains stable under different environmental conditions;

- High heat resistance: It can work normally in high-temperature environments;

- Strong corrosion resistance: It has good resistance to chemical substances.

- What are the application fields of Teflon F4B PCB?: Teflon F4B PCB is mainly applied in the following fields:

- Wireless communication: Such as mobile phones, base stations, satellite communication, etc.;

- Satellite navigation: Such as GPS, Beidou, etc.;

- Radar system: Including meteorological radar, aviation radar, etc.;

- Medical equipment: For example, high-frequency therapy equipment, etc.;

- Other high-frequency fields: Such as aerospace, military, etc.

- How to manufacture Teflon F4B PCB?: Manufacturing Teflon F4B PCB requires the following steps:

- Design the circuit board: Design the layout and traces of the PCB according to the circuit requirements;

- Material selection: Select an appropriate Teflon material as the substrate;

- Plate making: Produce PCB circuits through processes such as photolithography and etching;

- Surface treatment: Perform surface treatment on the PCB, such as gold plating, tin plating, etc., to improve solderability and corrosion resistance;

- Testing: Test the electrical performance of the manufactured PCB to ensure that it meets the requirements.

- How to choose a Teflon F4B PCB supplier?: When choosing a Teflon F4B PCB supplier, the following factors can be considered:

- Experience and reputation: Choose a supplier with rich experience and good reputation;

- Production capacity: Ensure that the supplier has sufficient production capacity to meet the demand;

- Quality control: Understand the supplier's quality control system and testing equipment;

- Price and delivery time: Consider the price and delivery time comprehensively and choose a supplier with high cost performance.

If you need more detailed and accurate information, it is recommended to consult a professional PCB manufacturer or supplier.