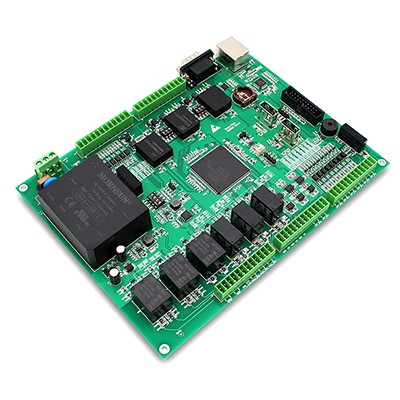

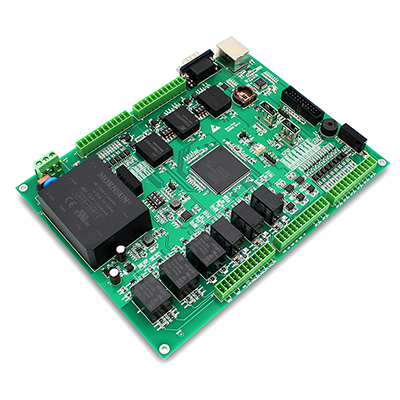

Description

layers:4

board thick:1.6mm

PCB & component assembly

copper thick:1oz

soldermask:green

silkscreen:white

surface treatment:immersion gold

The medical control PCBA (Printed Circuit Board Assembly), a printed circuit board assembly, is an electronic control circuit board specially designed and manufactured for medical devices.

The types of medical control PCBA boards?

Common types of medical control PCBA boards include:

1. Vital sign monitoring PCBA boards: Used for measuring and monitoring patients' vital signs, such as heart rate, blood pressure, respiratory rate, body temperature, etc.

The vital signs detection PCBA board is an electronic circuit board assembly specifically designed for measuring and monitoring human vital signs.

Vital signs typically include key indicators such as heart rate, blood pressure, respiratory rate, body temperature, and blood oxygen saturation. The vital signs detection PCBA board integrates a variety of sensors and electronic components to achieve precise measurement and data processing of these indicators.

In terms of sensors, it may be equipped with heart rate sensors, which detect the frequency and rhythm of heartbeats through photoelectric technology or electrodes; blood pressure sensors that use pressure sensing technology to measure blood pressure values; body temperature sensors, usually thermistors or thermocouples, for obtaining accurate body temperature data; respiratory rate sensors that can sense body movements or airflow changes caused by breathing; and blood oxygen saturation sensors that use spectral analysis to determine the oxygen content in the blood.

In terms of electronic components, it includes microcontrollers or processors responsible for receiving and processing signals from sensors, as well as performing data analysis and calculations. There may also be analog-to-digital converters (ADCs) to convert the analog signals from sensors into digital signals for processing by the microcontroller. Memory chips are used for temporarily storing measurement data, and communication modules are used for transmitting data to other devices or systems, such as medical monitors, mobile phone applications, or hospital information systems.

In addition, the vital signs detection PCBA board also needs to have good anti-interference ability to ensure accurate measurement in a complex electromagnetic environment. Its power management module needs to ensure a stable power supply to guarantee the normal operation of each component.

During the design and manufacturing process, the vital signs detection PCBA board needs to follow strict medical standards and regulations to ensure its accuracy, reliability, and safety. This type of board plays an important role in the medical field, such as hospital wards, emergency scenarios, home medical care, etc., providing medical staff with real-time and accurate patient vital signs information, which helps in making timely diagnosis and treatment decisions.

2. Diagnostic equipment PCBA boards: Control circuit boards for devices such as X-ray machines, CT scanners, ultrasound equipment, etc.

3. Therapeutic equipment PCBA boards: Control boards for devices like infusion pumps, laser therapy devices, electrotherapy equipment, etc.

4. Rehabilitation equipment PCBA boards: Control circuit boards for equipment used in assisted rehabilitation training, such as motion rehabilitation devices.

5. Medical imaging PCBA boards: Circuit boards for equipment such as magnetic resonance imaging (MRI), positron emission tomography (PET), etc.

6. In vitro diagnostic equipment PCBA boards: Control boards for devices such as blood analyzers, biochemical analyzers, etc.

7. Surgical equipment PCBA boards: Control circuit boards for surgical tools including surgical robots, electrosurgical knives, etc.

These are just some common types of medical control PCBA boards. The actual types will vary depending on the specific functions and applications of medical equipment.

What types of PCBA boards are used in medical PCBA boards? Such as flexible PCBA, rigid PCBA, etc.

Medical PCBA boards may use the following types of PCBA boards:

1. Rigid PCBA: This is the most common type, with high mechanical strength and stability, and is suitable for the main control part of most medical devices.

2. Flexible PCBA: It is flexible and can be bent and folded. It is often used in places where flexible wiring or connection of moving parts is required in a limited space, such as the movable probes in medical devices and the connection parts of foldable devices.

3. Rigid-Flex PCBA: It combines the characteristics of rigid and flexible boards. It has both certain mechanical strength and certain flexibility. It is suitable for complex medical device structures, such as some handheld medical detection devices.

4. HDI PCBA (High Density Interconnect PCBA): It can achieve finer circuits and higher wiring density. It is often used in medical devices with high requirements for space and performance, such as miniaturized diagnostic instruments.

5. Multi-layer PCBA: Composed of multiple alternating conductive and insulating layers, it can provide more wiring space and better signal isolation. It is suitable for medical devices with complex functions.

It should be noted that the specific type of PCBA board used depends on the specific requirements and design requirements of the medical device.

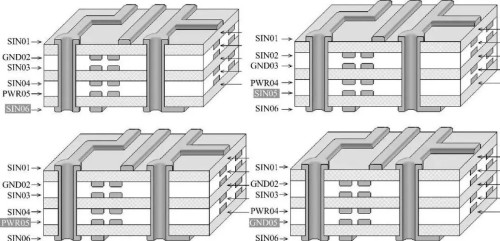

The lamination structure of multi-layer medical PCBA boards usually includes the following main parts:

1. Medical PCBA Core layer: This is the central part of the board, usually made of glass fiber-reinforced epoxy resin material (FR4), providing the main mechanical support and stability.

2. Medical PCBA Inner circuit layers: On both sides of the core layer, there will be one or more inner circuit layers made of copper foil, and the circuit traces are formed through processes such as etching.

3. Medical PCBA Insulation layers: Located between adjacent circuit layers, they play the role of electrical insulation to prevent short circuits between circuits, and are usually also made of materials such as epoxy resin.

4. Medical PCBA Prepreg: This is a semi-cured resin material used to bond the layers together and cure during the lamination process.

5. Medical PCBA Outer circuit layers: On the outermost layers of the board, there are also circuit layers made of copper foil for connecting external components and achieving signal transmission.

In medical applications, to meet the requirements of high reliability, high precision, and anti-interference, the lamination structure of multi-layer PCBA boards may adopt higher-quality materials and more strict manufacturing processes.

Flexible medical PCBA board

The lamination structure of the medical flexible PCBA board is usually composed of the following parts:

1. Medical PCBA Flexible substrate: Materials such as polyimide (PI) or polyester film (PET) are generally used to provide the characteristics of softness and flexibility.

2. Conductive layer of Medical PCBA: It is usually a thin copper foil, and the circuit lines are formed through etching or other processes.

3. Medical PCBA Adhesive layer: It is used to firmly bond the conductive layer to the flexible substrate.

4. Cover layer of Medical PCBA: It is usually also a flexible insulating material, such as PI or polyester, used to protect the conductive lines from environmental influences and mechanical damage.

In some complex designs, there may also include shielding layers, reinforcing layers, etc., to meet specific performance requirements.

Medical control board PCBA is an important part in medical devices, and mainly has the following functions:

- Control function: By receiving signals from sensors and switches, it controls the operating state of medical devices.

- Monitoring function: It monitors the working state of medical devices and the physiological parameters of patients in real time to help doctors detect abnormal situations in time.

- Adjustment function: It adjusts the parameters of medical devices according to the needs of doctors or patients to adapt to different medical scenarios.

- Maintenance function: It records the working state and usage of medical devices, provides alarm and maintenance prompts, and extends the service life of medical devices.

Here are some common application scenarios of medical control boards:

- Hospital equipment used medical PCBA: Such as surgical equipment, diagnostic equipment, therapeutic equipment, etc. The medical control board can realize the precise control and monitoring of these equipment to improve the safety and reliability of medical equipment.

- Rehabilitation equipment: Including rehabilitation trainers, prosthetics, wheelchairs, etc. The medical control board can adjust the parameters of the equipment according to the needs and rehabilitation progress of patients to provide personalized rehabilitation treatment.

- Medical robots with medical PCBA: For example, surgical robots, nursing robots, rehabilitation robots, etc. The medical control board can realize the motion control, perception feedback and task execution of the robots to improve the autonomy and accuracy of the medical robots.

- Telemedicine: Through the medical control board and communication technology, remote diagnosis, remote monitoring and remote treatment can be achieved to provide more convenient medical services for patients.

- Medical Internet of Things: The medical control board can be connected and communicate with other medical equipment and systems to form a medical Internet of Things, realize the collection, transmission and analysis of medical data, and provide support for medical decision-making.

1. The growth of the medical industry: With the global aging population, the increasing demand for healthcare, and the continuous advancement of medical technology, the medical equipment market continues to expand, thereby driving the demand for medical PCBA products.

2. Technological innovation: The emergence of new medical diagnosis and treatment technologies, such as telemedicine, minimally invasive surgical equipment, intelligent medical devices, etc., requires more advanced and complex PCBA to support their functions, which increases the value of medical PCBA products.

3. Stringent regulations and quality standards: Medical devices must comply with strict regulations and quality standards, which leads to increased production and testing costs of medical PCBA, thereby affecting its market value.

4. Customization demands: Many medical devices have unique functional and specification requirements, requiring customized PCBA design and manufacturing, which usually makes the products have higher value.

5. Supply chain stability: Ensuring a stable supply of components and a reliable production process is crucial for medical PCBA. Any disruption or uncertainty in the supply chain may affect the market value.

Due to the combined effect of these factors, the market value of medical PCBA products shows a stable growth trend. However, the specific market value may vary by region, product type, and market competition conditions. To obtain accurate and detailed market value data, it is necessary to refer to professional market research reports and industry analyses.