In-depth explanation of PCBs and how to fix PCB warpage?

[Read More] In order to improve your understanding, this article will be introduced to the method of repairing PCB warpage.PCB circuit board is one of the indispensable components of electronic equipment, many friends are to PCB production, PCB engraving, etc. as their work. To improve your understanding, this article will be introduced to the method of repairing PCB warpage. If you are interested in PCB or the content of this article, you may wish to come with me to continue reading down Oh.

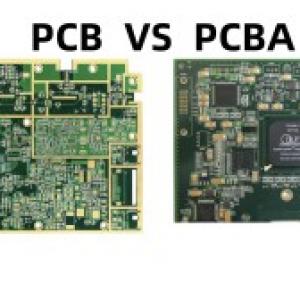

I. PCB

The creator of the PCB is the Austrian Paul eisler ( Paul eisler), in 1936, he first used the printed circuit board in the radio. 1943, the Americans more than the technology used in military radios, 1948, the United States officially recognized the invention can be used for commercial purposes. It was only since the mid-1950s that printed circuit boards have been widely used. Printed circuit boards can be found in almost every type of electronic device. The main function of the PCB is to make a variety of electronic components to form a predetermined circuit connection, the role of relay transmission, is the key electronic interconnections of electronic products, "the mother of electronic products" called.

Second, PCB warpage repair method

1, PCB process PCB warpage repair

In the PCB process, the warpage is relatively large plate through the roller leveler to pick out the leveling, and then into the next process. Many PCB manufacturers believe that this practice is effective in reducing the warpage rate of the finished PCB board.

2, PCB finished board warpage repair

For finished products, the warpage is obviously too poor to be levelled with a roller leveller. Some PCB factories will be put into a small press (or similar fixture) to press the warped PCB board, stay a few hours to ten hours for cold press leveling, from the practical application, the effect of this practice is not very obvious. First, the leveling effect is not great, the second is the pressure of the flattened board is easy to rebound (i.e. warp recovery).

Some PCB factories will be a small press heated to a certain temperature, and then the flattened PCB board for hot pressing, the effect will be better than cold pressing, but too much pressure will lead to wire deformation; if the temperature is too high will produce rosin discoloration and its discoloration and other defects. Moreover, either cold press levelling or hot press levelling takes a long time (a few hours to a dozen hours) to see the results, and the percentage of warped PCBs bouncing back after levelling is also high.

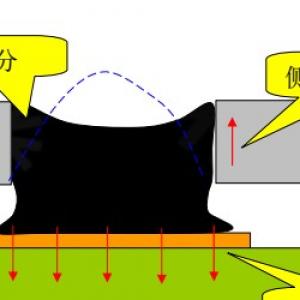

Here we recommend the hot press levelling method with a bow die. Depending on the PCB area to be levelled, a simple bow die is used. Here, two types of levelling operations are proposed.

1) Clamp the warped PCB into the bow die and bake it in the oven for levelling method.

The warped PCB board is bent to face the curved surface of the mould, adjust the clamping screws so that the PCB board is deformed and warped in the opposite direction, then the mould with the PCB board is put into the oven and heated to a certain temperature for baking and baked for a while. Under the heating conditions, the substrate stress gradually relaxed, the deformation of the PCB board back to a flat state. However, the baking temperature should not be too high to avoid discolouration of the rosin or yellowing of the substrate. However, the temperature should not be too low, it takes a long time to completely relax the stress at lower temperatures.

The glass transition temperature of the substrate can generally be used as a reference temperature for baking. The glass transition temperature is the phase change point of the resin, where the polymer chain segments can be rearranged to fully relax the stresses in the substrate.

Because of the obvious levelling effect, the advantage of flattening with a bow mould is that the investment is minimal. Ovens are available at the PCB factory. The levelling operation is very simple. If the number of warped boards is high, it is sufficient to make a few bow dies. You can put them into the oven once. With fewer moulds, the drying time is relatively short (a few minutes or so), so levelling is more efficient.

2) Softening the PCB and then clamping it into the bow mould to flatten the method.

For warpage deformation is relatively small PCB board, can be leveled PCB board into the oven has been heated to a certain temperature (that is, the temperature setting can be determined with reference to the glass transition temperature of the substrate, the substrate is baked in the oven for a certain period of time, observe the softening situation to determine. General glass fiber substrate baking temperature is higher, the paper substrate baking temperature can be lower; thick board baking temperature can be slightly higher, the thin board baking temperature can be slightly lower.

Sprayed rosin PCB board, baking temperature should not be too high. Bake for a certain amount of time, then take a few to a dozen, clip into the bow mold, adjust the pressure screw, and make the PCB board slightly warped and deformed in the opposite direction. After the board has cooled and set, the mould can be removed and the flattened PCB board can be taken out.

PCB board warpage is low after bow die flattening; even after wave soldering it can basically remain flat; the impact on PCB board appearance and colour is also minimal.