Analysis of the causes of cracks in repaired BGA

Huo Yiguo: Teachers, please help me find out why the BGA material on the product that has been repaired once has cracks after the Thermal cycle (1000 Cycles)?

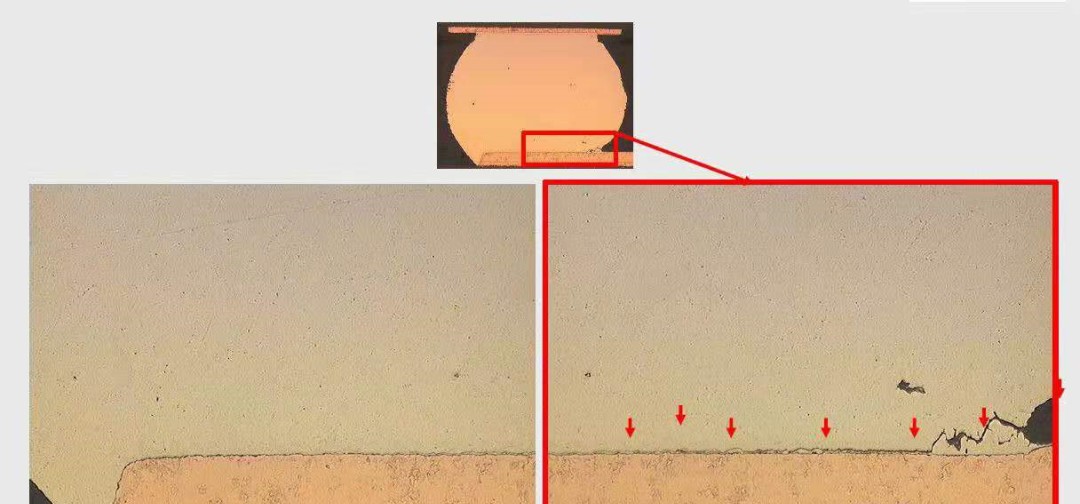

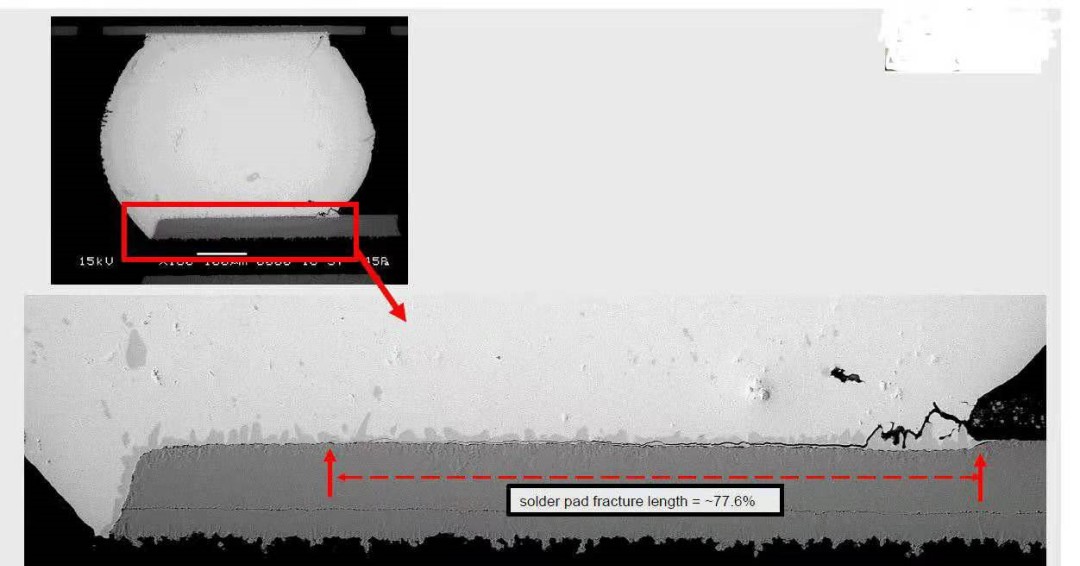

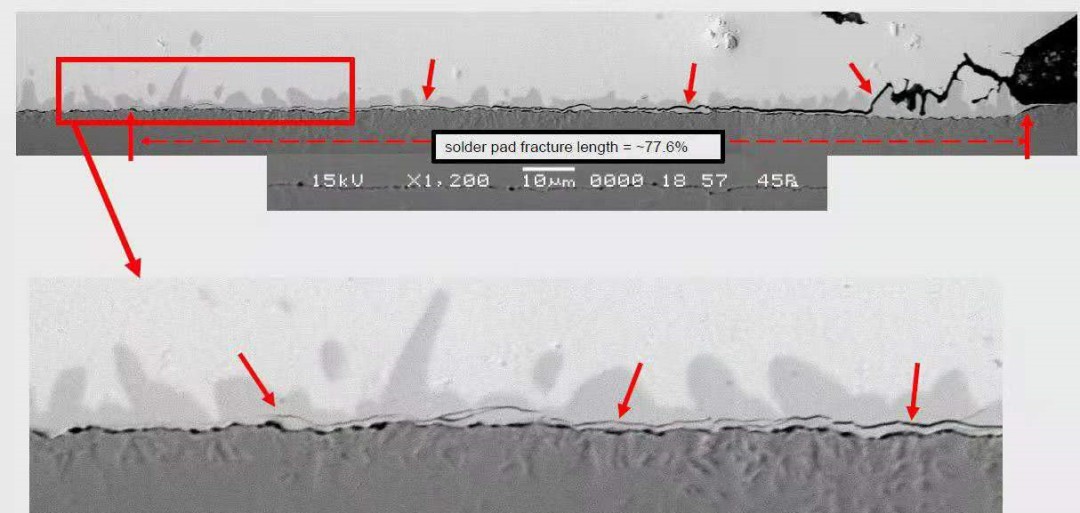

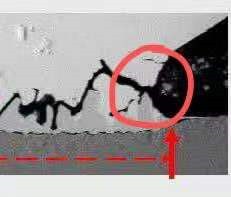

Wei Heng: The red circle in the picture shows that the crack starts from the middle of the solder ball and the alloy layer. It should be that the soldering was not done well after the rework. The alloy layer looks OK, which means that there is no problem with the first soldering. It should be that the solder ball and the alloy layer were not soldered well during the second soldering after the rework. The crack will start from this position and extend along the gap of the IMC layer...

Huo Yiguo: The starting point of the crack is on the outside of the solder ball?

Wei Heng: I feel that it is a problem during the second soldering. To put it bluntly, the solder ball is not completely fused with the IMC that has been formed after the first soldering. It may be related to temperature and time.

Xiao Wang: BGA can reach 1000 times, which is good. Even CCGA may not reach 1000 times.

Huo Yiguo: The key is that customers have requirements. If it cannot be achieved, we have to find a way.

Xiao Wang: Ceramic package BGA is generally more than 700 times. 1000 times requires soldering columns, which is very difficult.

Wei Heng: In addition, I feel that the direct cause of the fracture should still be stress... Imperfect welding is just a fuse. The test may pass, but once it is subjected to stress (PCB deformation or the way the staff holds the board), it is particularly prone to tin cracking. And from the picture, the source at the beginning is tin cracking. IMC has no problem.

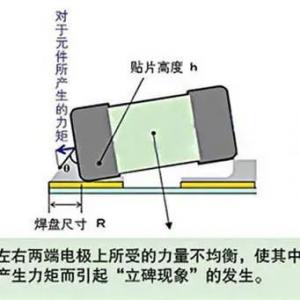

Liu Haiguang: The starting position of the fracture is quite special. Although the solder mask window is NSMD, the starting point is on the line side (seen as local SMD)... It should be caused by a problem with the rework technique. When removing tin, do not touch the PAD too much and keep appropriate solder. Heating and cooling should be in accordance with the specifications to prevent thermal tearing. Large-area fractures are between Cu6Sn5 and Cu3Sn or below Cu3Sn

Huo Yiguo: During the repair, I only used a soldering iron and flux to remove the tin, and did not use a wick.

After the BGA machine was used for repair, it was cooled on the machine for 5 minutes before being removed. All operations were performed according to normal techniques.

This series has nothing to do with the first normal reflow soldering (because the tin removal was not thorough)?

Liu Haiguang: The temperature of the soldering iron is generally high, and it will damage the IMC layer over time. Sometimes two layers of IMC will be disconnected.

Huo Yiguo: OK, thank you for your answers!