Discussion on the problem of tin beads growing out of the resistor after BGA rework

Discussion on the problem of tin beads growing out of the resistor after BGA rework

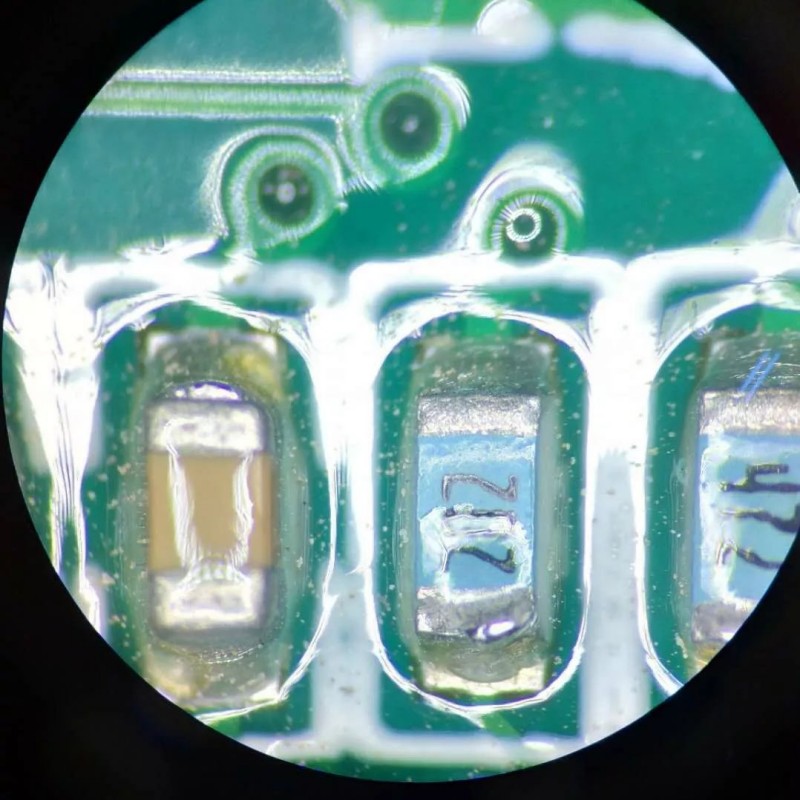

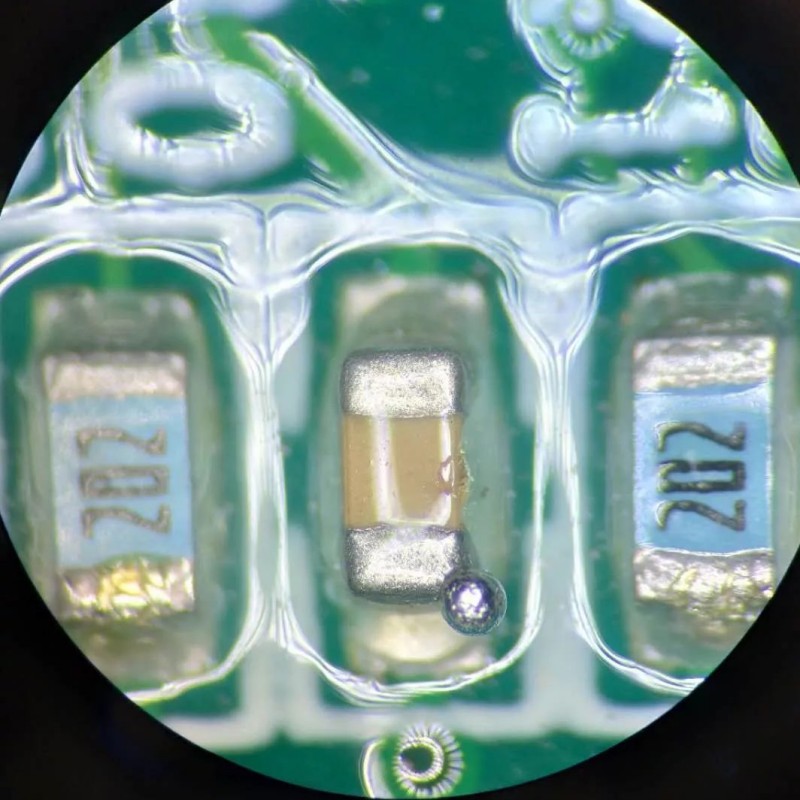

Chen Ji: BGA rework, next to the resistor on the growth of this tin bead, this teacher has encountered it?

Answer: conformal coating BGA repair after we are also in this situation! High-temperature tape to protect the unwanted places, choose and BGA matching head will improve!

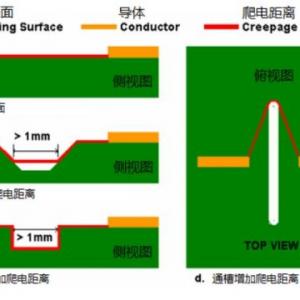

Qu Zhongbo: This is mainly due to the paint, when the rework, the place of the tin melted, the paint also became soft, under the action of the paint pressure, the tin agent out. We are now required to remove the lacquer within about 1cm outside the size of the nozzle @ Chen Ji

Tianya Wanderer: tin changes from solid to liquid, the volume expands, heat segregation

Chen Ji: I analyse the same situation, just want to know what is the solution, our paint is more difficult to remove, bga next to the device is good isolation, but there is also in the back of the bga @ Tianya Wanderer

QuZhongBo: if too close, high temperature tape is useless, paint remover

Chen Ji: If you use the ersa kind of infrared bga rework table will not be better? The impact on nearby devices is not so great.

Qu Zhongbo: If the upper and lower are infrared can not be, the heating range is too large, with high-temperature tape to protect the role of not much!

Tianya Wanderer : find a way to remove the glue first, try to soften with 150/160

Liu haiguang teacher: BGA bottom filler, desoldering peak temperature is too high, or the rate of heating is too large, the solder ball melting volume expansion will be spattered tin phenomenon occurs, the original filler glue before repair to be removed, otherwise the flux can not be overflowed, the same will be spattered and brought out of the solder @ chen ji