PCB design: PCB board design process

General pcb basic design process is as follows: pre-preparation -> PCB structure design -> PCB layout -> wiring -> wiring optimization and screen printing -> network and DRC check and structure check -> plate making.

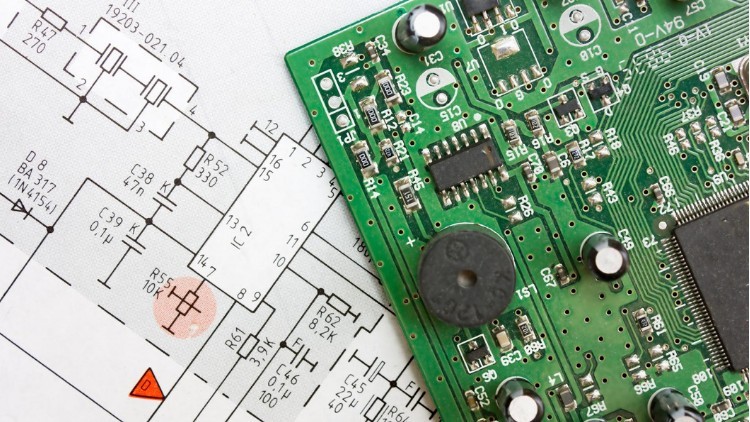

First: pre-preparation.

This includes the preparation of component libraries and schematics. "Work is good, it must be good", to make a good board, in addition to a good design principle, but also to draw well. Before proceeding with PCB design, first prepare the schematic SCH component library and the PCB component library. Component library can be used peotel comes with the library, but in general it is difficult to find the right one, it is best to make your own component library based on the standard size information of the selected device. In principle, first do the PCB component library, and then do the SCH component library. PCB component library requirements are higher, it directly affects the installation of the board; SCH component library requirements are relatively loose, as long as you pay attention to the definition of good pin properties and correspondence with the PCB components on the line. ps: pay attention to the standard library of hidden pins. After that is the design of the schematic, ready to start doing PCB design.

Second: PCB structure design.

This step according to the board size and the mechanical positioning has been determined, the PCB design environment to draw the pcb board surface, and positioning requirements to place the required connectors, keys / switches, screw holes, assembly holes, etc.. And fully consider and determine the wiring area and non-wiring areas (such as screw holes around how much range belongs to the non-wiring area).

Third: PCB layout.

Layout is, frankly speaking, put the device on the board. At this point, if the preparatory work mentioned earlier are done, you can generate a network table on the schematic (Design->CreateNetlist), and then import the network table on the PCB diagram (Design->LoadNets). You can see the device clatter all stacked up, and between the pins there are flying wires prompted to connect. Then you can layout the device. General layout according to the following principles: ①. According to the electrical properties of a reasonable partition, generally divided into: digital circuit area (that is, the fear of interference, and interference), analog circuit area (fear of interference), power drive area (interference sources); ②. Complete the same function of the circuit, should be placed as close as possible, and adjust the components to ensure the most concise connection; at the same time, adjust the relative position between the functional blocks to make the most concise connection between the functional blocks; ③. For the quality of large components should consider the installation location and installation strength; heat-generating components should be placed separately from temperature-sensitive components, if necessary, should also consider thermal convection measures; ④. I/O driver devices as close as possible to the side of the printed board, near the lead connector; ⑤. Clock generator (such as: crystal or clock oscillator) should be as close as possible to the device used for the clock; ⑥. In each integrated circuit between the power input pin and ground, you need to add a decoupling capacitor (generally using high-frequency performance of the monolithic capacitor); board space is dense, you can also add a tantalum capacitor around several integrated circuits. ⑦. Relay coil to add a discharge diode (1N4148 can be); ⑧. Layout requirements to be balanced, sparse and orderly, not top-heavy or a sink - need to pay special attention to the placement of components, be sure to consider the actual size of components (the area and height), the relative position between components to ensure the electrical performance of the board and the feasibility and convenience of production and installation at the same time, should be in To ensure that the above principles can be reflected under the premise of appropriate modifications to the placement of the device, so that it is neat and beautiful, such as the same device to be placed neatly, the same direction, can not be placed "staggered". This step is related to the overall image of the board and the difficulty of the next wiring, so a little effort should be put into consideration. Layout, not too sure of the place can be the first preliminary wiring, fully considered.

Fourth: Trace.

Tracing is the most important process in the entire PCB design. This will directly affect the performance of the PCB board good or bad. In the PCB design process, wiring generally has so three realms of division: First, the cloth through, which is the most basic requirements when designing PCBs. If the lines are not laid through, so that everywhere is a flying line, it will be a substandard board, so to speak, has not been introduced. The next is the electrical performance to meet. This is a measure of whether a printed circuit board qualified standards. This is after the cloth through, carefully adjust the wiring, so that it can achieve the best electrical performance. Then comes the aesthetics. If your wiring cloth through, there is nothing to affect the electrical performance of the place, but a glance at the past disorderly, plus colorful, flowery, green, that even if your electrical performance how good, in the eyes of others or a piece of garbage. This brings great inconvenience to testing and maintenance. The wiring should be neat and tidy, not crisscrossed without rules. These are to ensure the electrical performance and meet other individual requirements to achieve the case, otherwise it is to put the cart before the horse. The wiring should be done according to the following principles: ①. In general, the first should be wired for power and ground lines to ensure the electrical performance of the board. In the range of conditions, try to widen the power supply, ground line width, preferably wider than the power line, their relationship is: ground line > power line > signal line, usually the signal line width: 0.2 ~ 0.3mm, the thinnest width up to 0.05 ~ 0.07mm, the power line is generally 1.2 ~ 2.5mm. on the digital circuit PCB available wide ground wire to form a circuit, that is, to form A ground network to use (analog circuit ground can not be used in this way) ②. Pre-routing of the more stringent requirements of the line (such as high-frequency lines), the input and output side lines should be avoided adjacent to parallel, so as not to produce reflected interference. If necessary, ground isolation should be added, and the wiring of the two adjacent layers should be perpendicular to each other, and parallel is easy to produce parasitic coupling. ③. Oscillator shell grounding, the clock line should be as short as possible, and can not be led everywhere. Clock oscillation circuit below, special high-speed logic circuit part to increase the area of the ground, and should not go other signal lines to make the surrounding electric field tends to zero; ④. As far as possible, the use of 45o folding wiring, not 90o folding line to reduce the radiation of high-frequency signals; (high requirements of the line also use double-arc line) ⑤. Any signal lines do not form loops, such as unavoidable, loops should be as small as possible; signal lines should have as few holes as possible; ⑥. The key line as short and thick as possible, and add a protective ground on both sides. ⑦. Through the flat cable transmission of sensitive signals and noise field signals, to use the "ground - signal - ground" way to lead out. ⑧. Key signals should be reserved for test points to facilitate production and maintenance testing ⑨. After the schematic wiring is completed, the wiring should be optimized; at the same time, after the initial network check and DRC check is correct, the unwired area is filled with ground, with a large area of copper layer for the ground, in the printed circuit board is not used in the place are connected to the ground as the ground. Or make a multilayer board, power and ground each occupy a layer. --PCB wiring process requirements ①. In general, the signal line width of 0.3mm (12mil), the power line width of 0.77mm (30mil) or 1.27mm (50mil); between the line and the line and the distance between the line and the pad is greater than or equal to 0.33mm (13mil), the actual application, the conditions should be considered to increase the distance; wiring density is high, can be considered (but not recommended) to use IC pins go between two lines, the width of the line is 0.254mm (10mil), the line spacing is not less than 0.254mm (10mil). In special cases, when the device pins are denser and narrower width, the line width and line spacing can be reduced as appropriate. ②. Pad (PAD) Pad (PAD) and transition hole (VIA) the basic requirements are: the diameter of the disk than the diameter of the hole to be greater than 0.6mm; for example, general-purpose pin resistors, capacitors and integrated circuits, etc., using the disk / hole size 1.6mm / 0.8mm (63mil / 32mil), sockets, pins and diodes 1N4007, etc., using 1.8mm / 1.0mm (71mil/39mil). In practice, the actual application should be based on the size of the actual components to determine, when available, can be appropriate to increase the pad size; PCB board design of the component mounting aperture should be larger than the actual size of the component pins 0.2 ~ 0.4mm or so. ③. Over-hole (VIA) Generally 1.27mm/0.7mm (50mil/28mil); when the wiring density is high, the size of the over-hole can be reduced, but should not be too small, consider using 1.0mm/0.6mm (40mil/24mil). ④. Solder pad, line, over-hole spacing requirements PADandVIA: ≥ 0.3mm (12mil) PADandPAD: ≥ 0.3mm (12mil) PADandTRACK: ≥ 0.3mm (12mil) TRACKandTRACK: ≥ 0.3mm (12mil) When the density is high: PADandVIA: ≥ 0.254mm (10mil) 0.254mm (10mil) PADandPAD: ≥0.254mm (10mil) PADandTRACK: ≥0.254mm (10mil) TRACKandTRACK: ≥0.254mm (10mil)

Fifth: Tracing optimization and silkscreen.

"There is no best, only better"! No matter how much you dig into the design, when you finish drawing, and then go through it, you will still feel that many places can be modified. The general design experience is that it takes twice as long to optimize the wiring as it does to do the initial wiring. After you feel that there is no place to modify, you can lay copper (Place->polygonPlane). Copper laying generally laying ground (pay attention to the separation of analog ground and digital ground), multi-layer board may also need to lay power. When for silkscreen, be careful not to be blocked by the device or removed by the over-hole and pad. At the same time, the design is facing the component side, the word at the bottom should be done mirror image processing to avoid confusion level.

Sixth: network and DRC check and structure check.

First, to determine the circuit schematic design without error, the generated PCB network file with the schematic network file for the physical connection relationship network check (NETCHECK), and according to the output file results in a timely manner to amend the design to ensure the correctness of the wiring connection relationship; network check correctly passed, the PCB design for DRC check, and according to the output file results After the network check is passed correctly, the PCB design is DRC checked and the design is corrected according to the output file results in time to ensure the electrical performance of the PCB wiring. Finally, the mechanical installation structure of the PCB needs to be further checked and confirmed.

Seventh: plate making.

Before that, it is best to have a review process. PCB design is an examination of the work of the mind, who has a dense mind, high experience, the design of the board will be good. So the design should be extremely careful, fully consider all aspects of the factors (for example, to facilitate maintenance and inspection of this item many people do not consider), excellence, you will be able to design a good board.