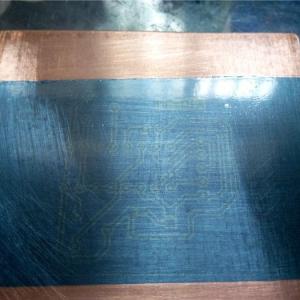

Analysis and discussion on the cause of slight stains on the PCBA coating?

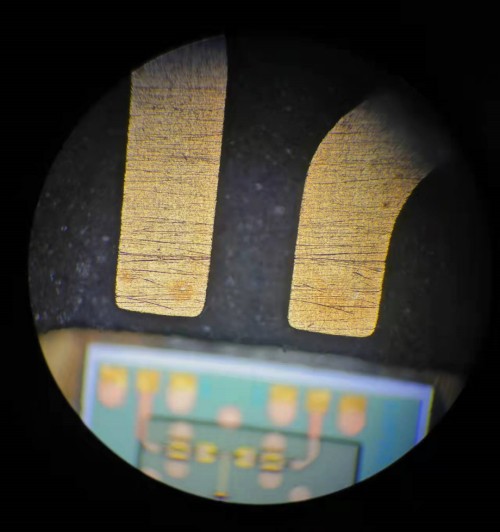

Jane: Teachers, the gold wire cannot be hit, nickel-palladium-gold plating. How can we ensure that there is no such slight stain on the plating after welding?

Alina: I have encountered it before. It is recommended to clean and dry it in time after welding and put it in an anti-static drying cabinet

Jane: It is cleaned in time

Ding Jinglei: Remedial solution: You can try tinning, a thin layer, and then bond the gold strip or gold wire

Liao Xiaobo: If you confirm that it is caused by "organic pollution", use atmospheric plasma "flame" to clean it once, there will be obvious improvement. Of course, vacuum plasma cleaning will be better.

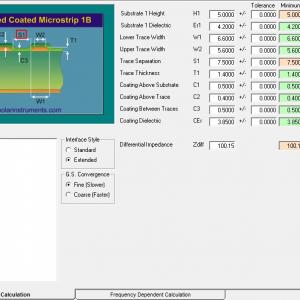

At present, atmospheric plasma cleaning machines can be purchased for 30,000 to 50,000. What is the working (welding) principle of your "gold wire" machine?

Jane: Vacuum plasma cleaning is used, and the gold wire is ultrasonic hot pressing welding

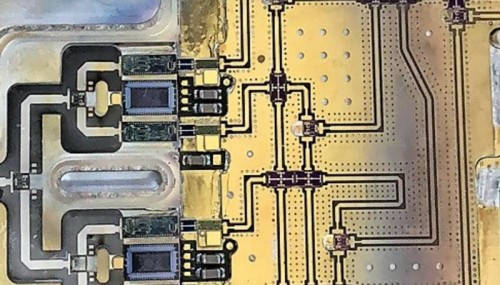

Liu Haiguang: Check whether the filtration system of the vacuum plasma cleaning machine is normal. Because of the large amount of solid crystal flux, the filtration is not good and pollution is everywhere.

Jane: The vacuum has been taken away, and there is still pollution?

Liao Xiaobo: Plasma is very effective in removing fingerprints, sweat stains, and trace organic pollutants co-deposited (adsorbed) with electroplating and chemical nickel-gold plating! But it is helpless in removing metal oxides. If there are oxides on the surface of the plating of your gold wire bonding structure (improper storage, or exceeding the effective storage period), then plasma cleaning is powerless.

Liu Haiguang: Plasma cleaning before solid crystal, compare the effect, and clean twice to see the effect

How to solve the problem: Which cleaning method is better for lead-free and no-clean flux? How is the effect of trichloroethylene vacuum gas phase cleaning?

Liu Haiguang: Plasma cleaning is not used to deal with flux, gas phase can, too much flux will make plasma cleaning agent overloaded

Jane: Your pollution is very serious

Liu Haiguang: There is too much flux on the board, the filtration system is not matched, and there is indigestion

Forget-me-not: Trichloroethylene is a carcinogen, and VOC is also high

Fish head: Freon, trichloroethylene, and trichloromethane were banned and restricted here about ten years ago, and ordinary companies cannot purchase them.

Now the purchase of chemicals such as xylene must be approved by the government management department, and a distribution record must be established when using them.

Xu Zhonglie: The effect of trichloroethylene in washing boards is OK.

Liu Haiguang: Whether it is a carcinogen or a high VOC, before there are alternative materials or solutions, it is just a matter of protection and collection modification... Don't think too much. Many quality problems are caused by the poor effect of so-called environmentally friendly materials.

Forget-me-not: There are definitely alternatives. The key is that many people only look at the cleaning effect. The selection of cleaning agents does not only consider this point~

Liu Haiguang: What is needed is how to decompose toxic or banned materials, compress emissions to the allowable range, and other things are lies without equipment updates.

Forget-me-not: Environmental protection is not a small issue now. For example, if the VOC is high, the one with less toxicity must be selected, including comprehensive cost considerations. It is meaningless to only talk about the cleaning effect.

You Ran: The volatile matter content of all cleaning fluids must pass the national standard 38508 in 2021. This is a mandatory standard, otherwise it cannot be put on the market.

Xu Zhonglie: It is difficult to wash boards.

You Ran: It depends on the effect of the cleaning fluid. It must be low in volatility and clean. For the sake of environmental protection, the cleaning cost will increase, that's for sure.

Forget-me-not: That's right, organic solvents all have VOC, flash point, toxicity and other problems, but the parameters of each are different, so they need to be considered comprehensively with the cleaning effect.

Anti-chlorine solvents such as anti-dichloroethylene have the same cleaning effect as trichloroethylene and tetrachloroethylene, but anti-chlorine is much less toxic, and the VOC is the same, but the cost performance is low

Farary: The GB38508 standard is exempted for aerospace, nuclear industry, military and other products

Forget-me-not: Organic solvents used for manual cleaning, trichloroethylene, tetrachloroethylene, and propane bromide are all Class I and Class II carcinogens, advantages: no flash point (not flammable and explosive, no need to consider environmental storage explosion-proof), good cleaning effect, cheap

Alcohols (ethanol, isopropanol), etc., hydrocarbons (such as aviation gasoline, different carbon-hydrogen atomic ratios, many types) are all general cleaning effects, but flammable and explosive (explosion-proof safety treatment is required during storage and use), and low toxicity.

Anti-chlorine (anti-dichloroethylene), although it also contains chlorine, has very low toxicity and is not included in the three categories of hazardous substances (there are related literatures that have done anti-chlorine mouse tests), with good cleaning effects, but the disadvantage is that the price is slightly higher

The basic components of composite manual cleaning agents are composite solvents of mixed alcohols, hydrocarbons, halogenated hydrocarbons, etc. (the proportions of various models are different, and the ingredients are slightly adjusted). The cleaning effect is a little better than these single substance components. For other properties, refer to the properties of single substances, and SDS data can also be used as a reference.

The properties of other new compounds are not evaluated without a deeper understanding~

Forget-me-not: As a process selection manual cleaning agent, I would rather choose flammable and explosive ones (low flash point) to let the company spend money on explosion-proof safety treatment during storage and use, or choose anti-chlorine.

I don't want to choose Class I and Class II toxic substances such as trichloroethylene and n-propane. It is unrealistic to require workers to wear toxic masks every day as a toxic protection measure. It is more meaningful to put yourself in the shoes of front-line workers and consider their occupational health than to simply consider the cleaning effect.

Hong: Manual washing, alcohol is the simplest.

Xu Zhonglie: The cleaning effect is not good and delivery is difficult. Which one should be preferred between methanol and ethanol?

Liu Haiguang: The two can be mixed in proportion, and the solubility is better

Forget-me-not: Ethanol is better. Alcohols have good solubility in polarity and non-polarity. Alcohol cleaning has both dissolution and the process of alcohol and rosin acid reacting to form esters. I think ethanol and isopropanol are better. The volatility of alcohols is relatively high (VOC), so forget about methanol

Liu Haiguang: Cleaning flux is no problem, it has nothing to do with ion pollution. The cleaning effect depends on swelling and dissolution. 4% acetone + isopropanol is better

Forget-me-not: The disadvantage of manual cleaning is not the cleaning agent. There are so many BTC (bottom terminal devices) on the board now. Manual cleaning has no spray pressure, which is basically useless for such devices, including those with fine spacing.

The ion contamination test is also the average value of the PCBA. It has no practical significance for whether the local ion residue on the board exceeds the standard or not.

Liu Haiguang: That is an equipment problem. The gas phase cannot remove nano-level pollutants.

Peter: Yes, I learned that the vapor phase cleaning only relies on the evaporation and dissolution of the solvent. The effect is generally poor. The manufacturer actually adds an ultrasonic device to wash it again.

He Yi Jieyou: Thank you for the Q&A and discussion of all the teachers. I have learned a lot!