Skills of manual soldering of chip electronic components

Skills of manual soldering of chip electronic componentsWith the advancement of the times and technology, more and more circuit boards are now using chip components. Chip components are becoming more and more popular with everyone because of their small size and easy maintenance. But for many people, they feel "afraid" of chip components, especially for some beginners, because they think they do not have the ability to solder components and feel that it is not as easy to solder as traditional plug-in components. In fact, these concerns are completely unnecessary. Readers can use appropriate tools and master some knowledge of manual soldering patches, and they will soon become experts in soldering chip components.

1. Benefits of using chip components

First, let's understand the benefits of chip components. Compared with lead components, chip components have many advantages. The first aspect: small size, light weight, easy to store and mail. For example, the commonly used chip resistors 0805 package or 0603 package are much smaller than the plug-in resistors we used before. Dozens of plug-in resistors can fill a bag, but if they are replaced with chip resistors, they are enough to hold thousands or even tens of thousands. Of course, this is without considering the maximum current it can withstand. Second aspect: SMD components are easier to solder and disassemble than DIP components. SMD components do not require vias and use less tin. The most troublesome and stressful thing about DIP components is disassembly. Friends who have done it all have this experience. On a PCB board with two or more layers, even if there are only two pins, it is not easy to disassemble and it is easy to damage the circuit board, not to mention the multi-pin ones. It is much easier to disassemble SMD components. Not only are two pins easy to disassemble, but even if components with one or two hundred pins are disassembled several times, the circuit board will not be damaged. Third aspect: SMD components have another very important benefit, which is to improve the stability and reliability of the circuit, which increases the success rate of production.

This is because SMD components are small in size and do not require vias, thereby reducing stray electric and magnetic fields, which is particularly important in high-frequency analog circuits and high-speed digital circuits. In summary, the author can take "responsibility" to say that once you adapt to and accept SMD components, you may never want to use DIP components again unless you have to.

2. Common tools for soldering SMD components

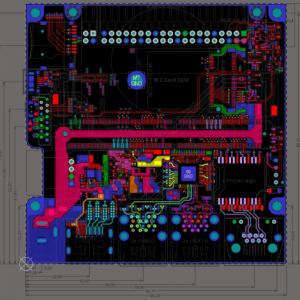

After understanding the benefits of SMD components, let's learn about some basic tools commonly used for soldering SMD components (see Figure 1).

Figure 1 Common tools used for manual soldering of SMD components

1. Electric soldering iron

This is definitely indispensable for manual soldering of components. Here I recommend the kind with a sharper soldering iron tip, because when soldering SMD chips with dense pins, it can accurately and conveniently solder one or several pins.

2. Solder wire

Good solder wire is also very important for SMD soldering. If conditions permit, when soldering SMD components, use thin solder wire as much as possible, so that it is easy to control the amount of solder, so as not to waste solder and suck tin.

3. Tweezers

The main function of tweezers is to facilitate the clamping and placement of SMD components. For example, when soldering SMD resistors, you can use tweezers to clamp the resistors and place them on the circuit board for soldering. Tweezers require a sharp and flat front end to facilitate clamping components. In addition, for some chips that need to prevent static electricity, anti-static tweezers are needed.

4. Soldering tape

When soldering SMD components, it is easy to over-tin.

Especially when soldering dense multi-pin SMD chips, it is easy to cause the two or even multiple adjacent pins of the chip to be short-circuited by solder. At this time, the traditional solder sucker is useless, and a braided soldering tape is needed.

Soldering tape can be bought at places where welding equipment is sold. If you don’t have it, you can also use the copper wire in the wire instead, which will be described later.

5. Rosin

Rosin is the most commonly used flux in welding, because it can precipitate oxides in the solder, protect the solder from oxidation, and increase the fluidity of the solder. When soldering direct-insert components, if the components are rusted, scrape them first, put them on the rosin and iron them with a soldering iron, and then tin them. When soldering SMD components, in addition to the fluxing function, rosin can also be used as a soldering tape with copper wire.

6. Solder paste

When soldering iron parts that are difficult to tin, solder paste can be used. It can remove oxides on the metal surface and is corrosive.

When soldering SMD components, it can sometimes be used to "eat" solder to make the solder joints shiny and firm.

7. Hot air gun

A hot air gun is a tool that uses the hot air blown out of its gun core to solder and disassemble components. The process requirements for its use are relatively high.

A hot air gun can be used from removing or installing small components to large integrated circuits. In different occasions, there are special requirements for the temperature and air volume of the hot air gun. Too low temperature will cause component cold soldering, and too high temperature will damage components and circuit boards. Too much air volume will blow away small components. For ordinary SMD welding, hot air guns are not required, and will not be described in detail here.

8. Magnifying glass

For some SMD chips with particularly small and dense pins, after soldering, it is necessary to check whether the pins are soldered normally and whether there is a short circuit. At this time, it is very laborious to use the human eye, so a magnifying glass can be used to conveniently and reliably check the soldering status of each pin.

9. Alcohol

When using rosin as a flux, it is easy to leave excess rosin on the circuit board. For the sake of beauty, you can use an alcohol cotton ball to wipe the residual rosin on the circuit board. 10. In addition to the above, there are some other common tools required for SMD soldering, such as sponges, board washing water, hard brushes, glue, etc. I will not go into details here. Friends who have the conditions can understand and practice them.

(From left to right, the first row is: hot air gun, tweezers, solder wire. The second row is: electric soldering iron, rosin, tin-absorbing tape)

III. Manual soldering steps of SMD components

After understanding the SMD soldering tools, the soldering steps are now described in detail.

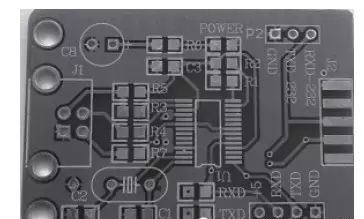

1. Clean and fix the PCB (printed circuit board)

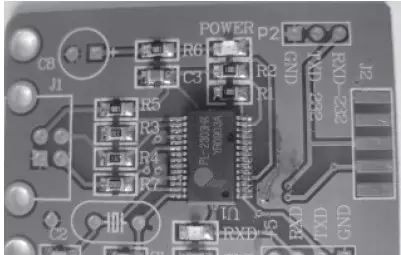

Before soldering, check the PCB to be soldered to ensure that it is clean (see Figure 2). Remove the oily fingerprints and oxides on the surface so as not to affect the tinning. When manually soldering the PCB, if conditions permit, you can use a soldering station or something like that to fix it so as to facilitate soldering. Generally, you can just fix it with your hands. It is worth noting that you should avoid touching the pads on the PCB with your fingers to affect the tinning.

Figure 2 A clean PCB

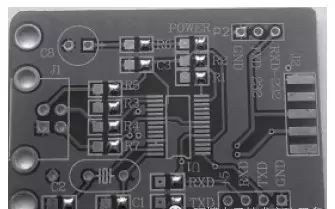

2. Fixing SMD components

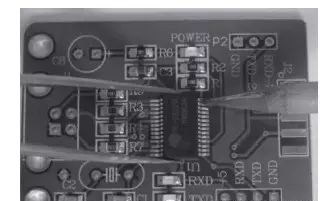

It is very important to fix the SMD components. According to the number of pins of the SMD components, the fixing methods can be roughly divided into two types - single-pin fixing method and multi-pin fixing method. For SMD components with a small number of pins (generally 2-5) such as resistors, capacitors, diodes, transistors, etc., the single-pin fixing method is generally used. That is, first tin one of its pads on the board (see Figure 3).

Figure 3 For components with few pins, tin one pin first

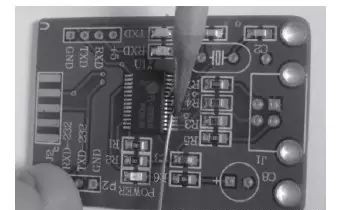

Then hold the component with tweezers in your left hand and place it in the installation position and lightly press against the circuit board. Hold the soldering iron in your right hand close to the tinned pad to melt the solder and solder the pin (see Figure 4). After soldering a pad, the component will not move, and the tweezers can be loosened at this time. For SMD chips with many pins and multi-sided distribution, it is difficult to fix the chip with one pin. At this time, multiple pins are required for fixing. Generally, the method of pin-to-pin fixing can be used (see Figure 5). That is, after soldering and fixing one pin, solder and fix the pin opposite to the pin, so as to achieve the purpose of fixing the entire chip. It should be noted that for SMD chips with many and dense pins, accurate pin alignment with pads is particularly important and should be carefully checked and verified, because the quality of welding is determined by this premise.

Figure 4 Fixing and welding components with fewer pins

Figure 5 Fixing and welding components with more pins

It is worth emphasizing that the pins of the chip must be correctly judged.

For example, sometimes we carefully fix the chip and even complete the welding, but when checking, we find that the pins correspond incorrectly - the pin that is not the first pin is welded as the first pin! Regret it! Therefore, these meticulous preliminary work must not be sloppy.

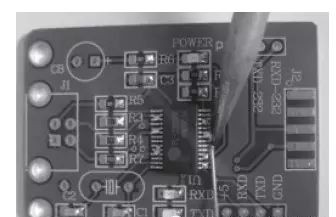

3. Welding the remaining pins

After the component is fixed, the remaining pins should be welded. For components with fewer pins, you can hold the solder in your left hand and the soldering iron in your right hand, and spot weld them in turn. For chips with many and dense pins, in addition to spot welding, you can use drag welding, that is, apply enough solder to the pins on one side and then use the soldering iron to melt the solder and wipe it on the remaining pins on that side (see Figure 6). The molten solder can flow, so sometimes you can also tilt the board appropriately to remove the excess solder. It is worth noting that, whether spot welding or drag soldering, it is easy to cause adjacent pins to be short-circuited by tin (see Figure 7). Don't worry about this, because it can be done. What you need to care about is that all pins are well connected to the pads and there is no cold solder.

Figure 6 Drag soldering for SMD chips with more pins

Figure 7 Don't worry about pin short circuits caused by welding

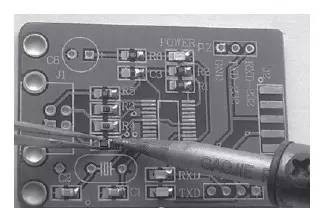

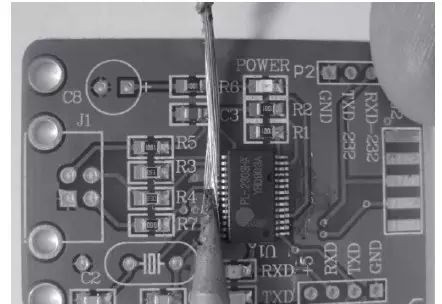

4. Remove excess solder

In step 3, the pin short circuit phenomenon caused by welding was mentioned. Now let's talk about how to deal with this excess solder. Generally speaking, you can use the tin-absorbing tape mentioned above to absorb the excess solder. The method of using tin-absorbing tape is very simple. Add an appropriate amount of flux (such as rosin) to the tin-absorbing tape and then stick it close to the pad. Put a clean soldering iron tip on the tin-absorbing tape. After the tin-absorbing tape is heated to melt the solder on the pad to be absorbed, slowly press and drag it from one end of the pad to the other end, and the solder will be sucked into the tape. It should be noted that after the desoldering is completed, the soldering iron tip and the tin-absorbing tin strip should be removed from the soldering pad at the same time. If the tin-absorbing tin strip sticks to the soldering pad, do not pull the tin-absorbing tin strip hard. Instead, add flux to the tin-absorbing tin strip or reheat it with the soldering iron tip and then gently pull the tin-absorbing tin strip to make it smoothly separate from the soldering pad and prevent the surrounding components from being burned. If there is no special tin-absorbing tin strip sold on the market, you can use the thin copper wire in the wire to make your own tin-absorbing tin strip (see Figure 8). The homemade method is as follows: After peeling off the outer skin of the wire, the thin copper wire inside is exposed. At this time, use a soldering iron to melt some rosin on the copper wire. The effect after removing the excess solder is shown in Figure 9. In addition, if you are not satisfied with the welding result, you can reuse the tin-absorbing tin strip to remove the solder and solder the components again.

Picture 8 Use a homemade desoldering tape to absorb excess solder from the chip pins

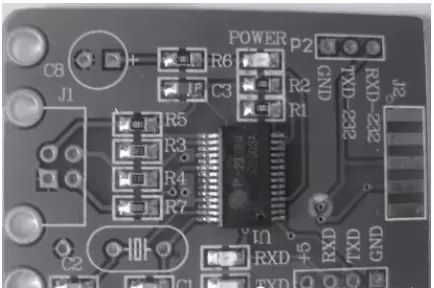

Picture 9 Effect picture after removing excess solder from the chip pins

5. Clean the soldering area

After soldering and removing excess solder, the chip is basically soldered. However, due to the use of rosin flux and desoldering tape to absorb tin, some rosin remains around the chip pins on the board (see Figure 9). Although it does not affect the operation and normal use of the chip, it is not beautiful. And it may cause inconvenience during inspection. Because it is necessary to clean these residues. The common cleaning method can be to use board washing water. Here, alcohol cleaning is used. The cleaning tool can be a cotton swab, or it can be used with tweezers holding toilet paper (see Figure 10). When cleaning and erasing, it should be noted that the alcohol should be appropriate, and its concentration should be higher to quickly dissolve residues such as rosin. Secondly, the force of erasing should be controlled well, not too large, so as not to scratch the solder mask and damage the chip pins. The effect after cleaning is shown in Figure 11. At this time, you can use a soldering iron or a hot air gun to properly heat the alcohol-wiping position to allow the residual alcohol to evaporate quickly. At this point, the chip welding is over.

Figure 10 Use alcohol to remove the rosin left during welding

Figure 11 The effect of cleaning the welding position with alcohol

IV. Summary

In summary, welding SMD components is generally a process of fixing-welding-cleaning. Among them, the fixing of components is the premise of good welding. You must be patient and ensure that each pin and its corresponding pad are accurately aligned. When welding multi-pin chips, don't worry about the pins being short-circuited by solder. You can use tin-absorbing tape for soldering or just use a soldering iron to remove excess solder by taking advantage of the flow of solder after melting. Of course, mastering these skills requires practice. Due to space limitations, this article only demonstrates the welding of a multi-pin chip. For many other types of multi-pin SMD chips, the corresponding welding methods are basically the same under different circumstances, such as the density of pins, mechanical strength, and quantity, but the details are slightly different. Therefore, if you want to become a master at soldering SMD components, you need to practice more to improve your proficiency. If conditions permit, you can use old circuit boards and old chips to improve your proficiency.