Description

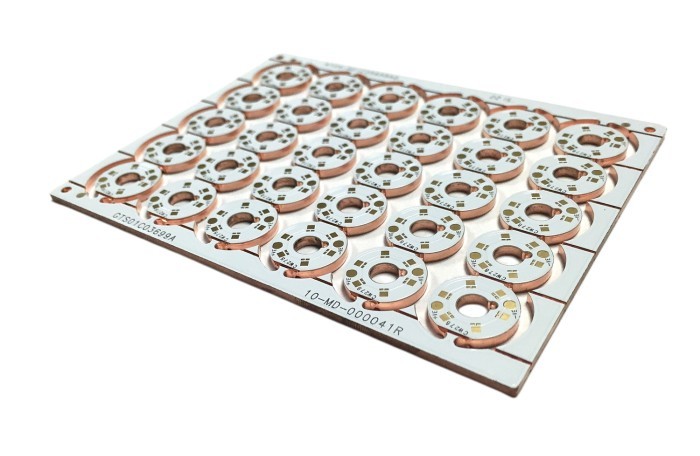

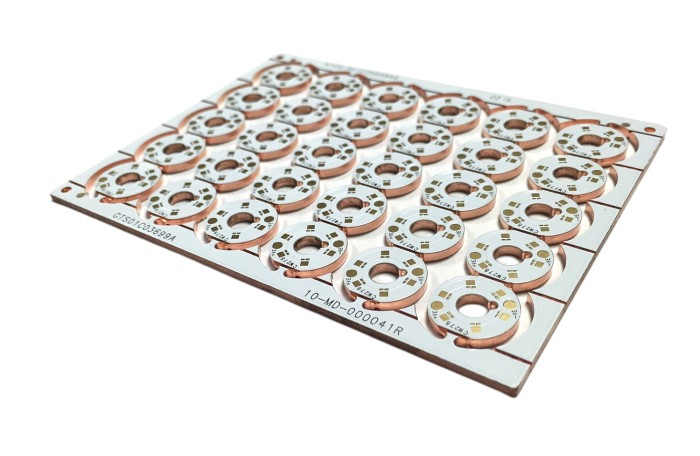

board thick:2.0MM

size:220x160mm

inner hole thick:25um

soldermask:whitesurface finish:immersion gold; Au>=1"

E-Test

100% Computer open short circuit test

lead time:10working days

Application:Power Supply

The main characteristics of copper substrate PCB are as follows:

- Excellent heat dissipation performance: The copper substrate has good thermal conductivity and can effectively dissipate the heat generated by electronic components on the PCB, thus ensuring the stable operation of electronic equipment.

- Good mechanical processing performance: The copper substrate has relatively high mechanical strength and toughness, and large-area printed circuit boards can be fabricated on it, and mechanical processing such as hammering, riveting, bending, and twisting can be carried out.

- High dimensional stability: The dimensional stability of the copper substrate is better than that of general resin substrates and is closer to the linear expansion coefficient of copper, which is beneficial to ensuring the quality and reliability of the printed circuit.

- Good electromagnetic shielding: The copper substrate can act as a shielding plate to play the role of shielding electromagnetic waves, thereby ensuring the performance of the electronic circuit.

- Wide application fields: The copper substrate is mainly suitable for high-frequency circuits, including the heat dissipation of precision communication equipment in areas with large temperature changes.

Common types of copper substrate PCB include immersion gold copper substrate, silver-plated copper substrate, tin-sprayed copper substrate and anti-oxidation copper substrate, etc.

The immersion gold copper substrate has good solderability and corrosion resistance, and a smooth surface, which is suitable for high-precision and high-reliability electronic devices.

The silver-plated copper substrate has better thermal conductivity and is often used in high-frequency circuits and occasions with high heat dissipation requirements.

The tin-sprayed copper substrate has good soldering performance and mechanical strength and is suitable for ordinary electronic devices.

The anti-oxidation copper substrate has good anti-oxidation performance after special treatment, which can extend the service life of the PCB.

When choosing a copper substrate PCB, comprehensive consideration needs to be given according to the specific application requirements and performance requirements. Different types of copper substrate PCB may vary in terms of performance, cost and applicable scenarios.