Why does the needle weld off with only copper and nickel, no tin, lead, gold, etc.?

Why does the needle come off with only copper and nickel, no tin, lead, gold, etc.?

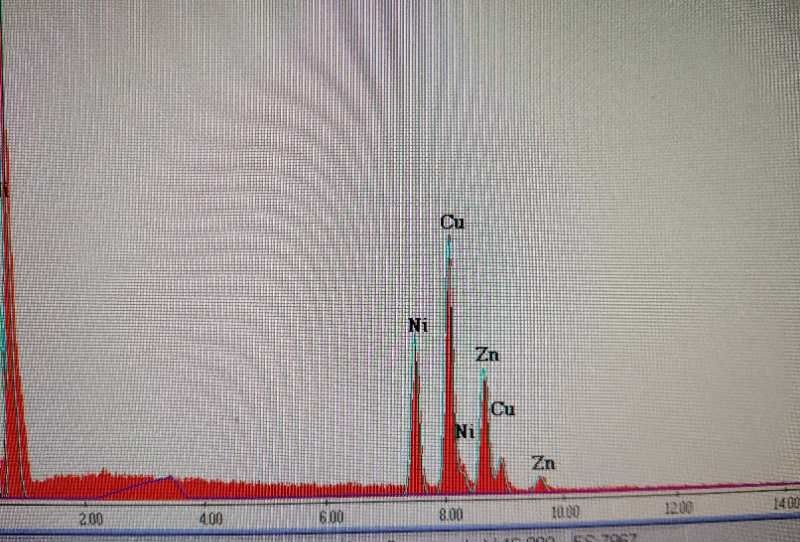

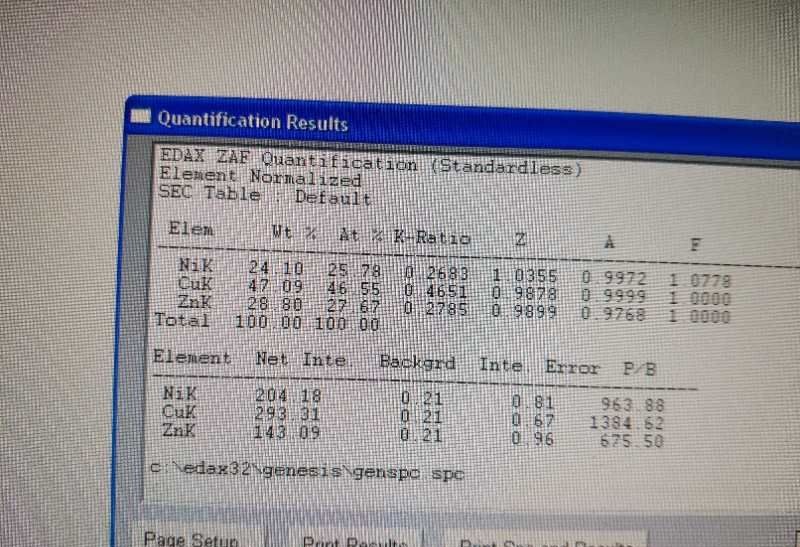

Zhao Libo: I would like to ask about this fallen needle. The test found that the surface of the welding surface only has copper and nickel, no tin, lead, gold and other ingredients. Instead, there is more zinc. Will gold brittleness cause this result?

Liao Xiaobo: The extra zinc may be the alloying element in the gold needle matrix H62 brass (copper-zinc alloy). Usually, when the gold coating on the bottom of nickel is very thin, the X-ray tester may be sensitive to the alloying elements in the base metal @赵立博

Zhao Libo: Okay, I know about the zinc, thank you!

I would also like to ask if the gold-plated pins fall off after welding and there is no gold, tin or lead on the surface of the gold-plated side. Is this normal?

Liao Xiaobo: The coating test results show that the gold thickness is very small, so there is no talk of "gold brittle".

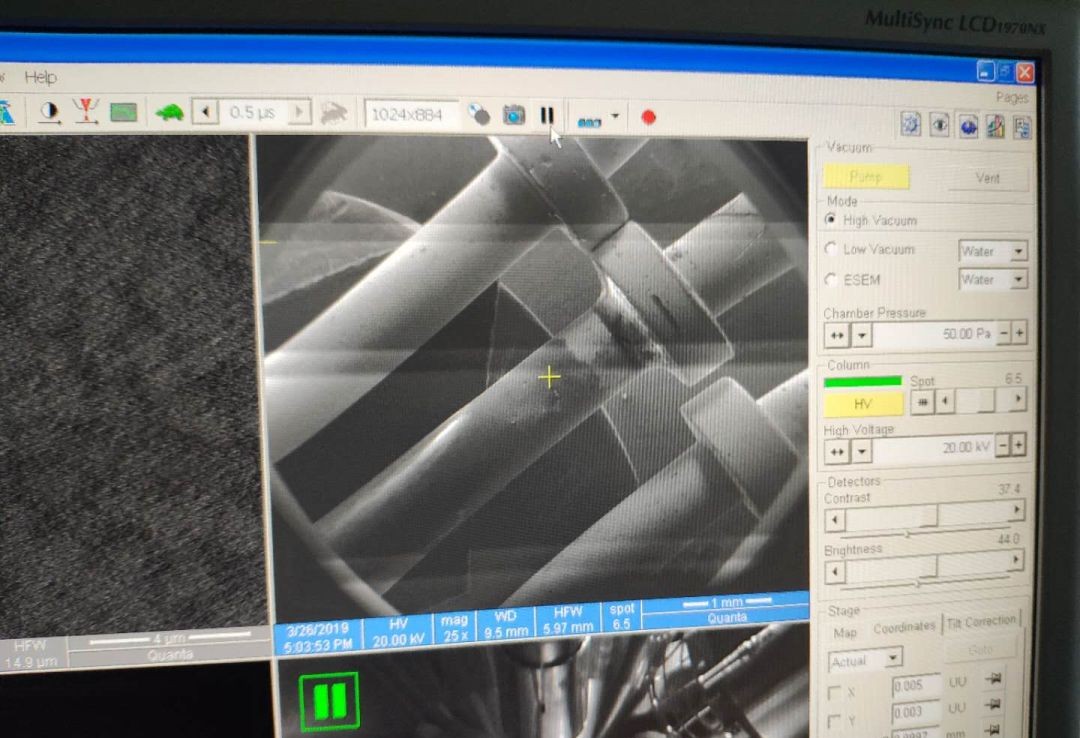

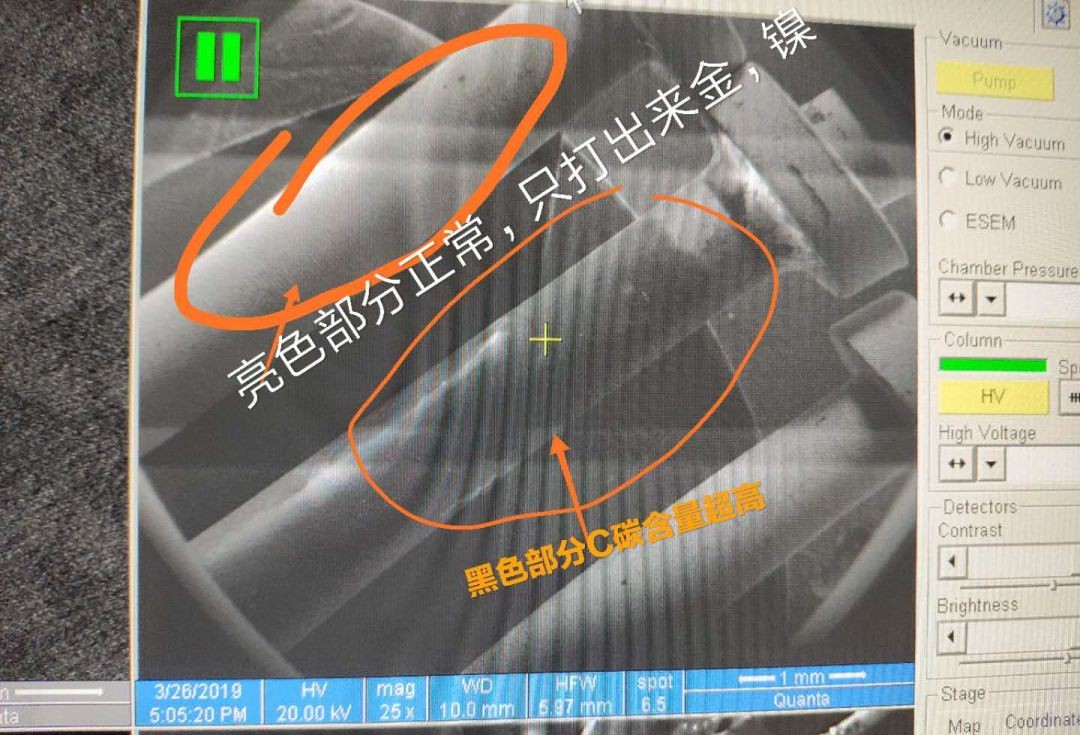

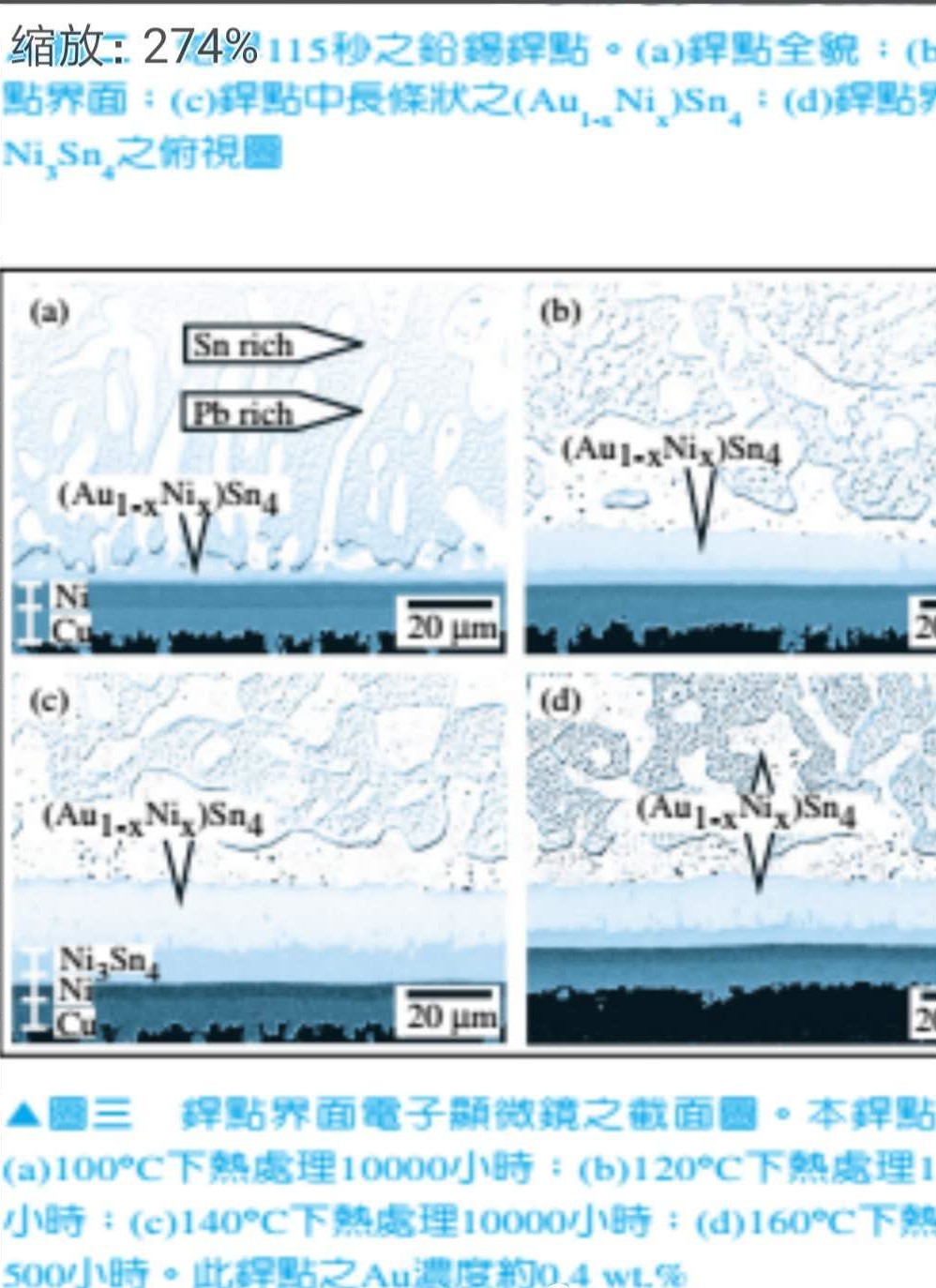

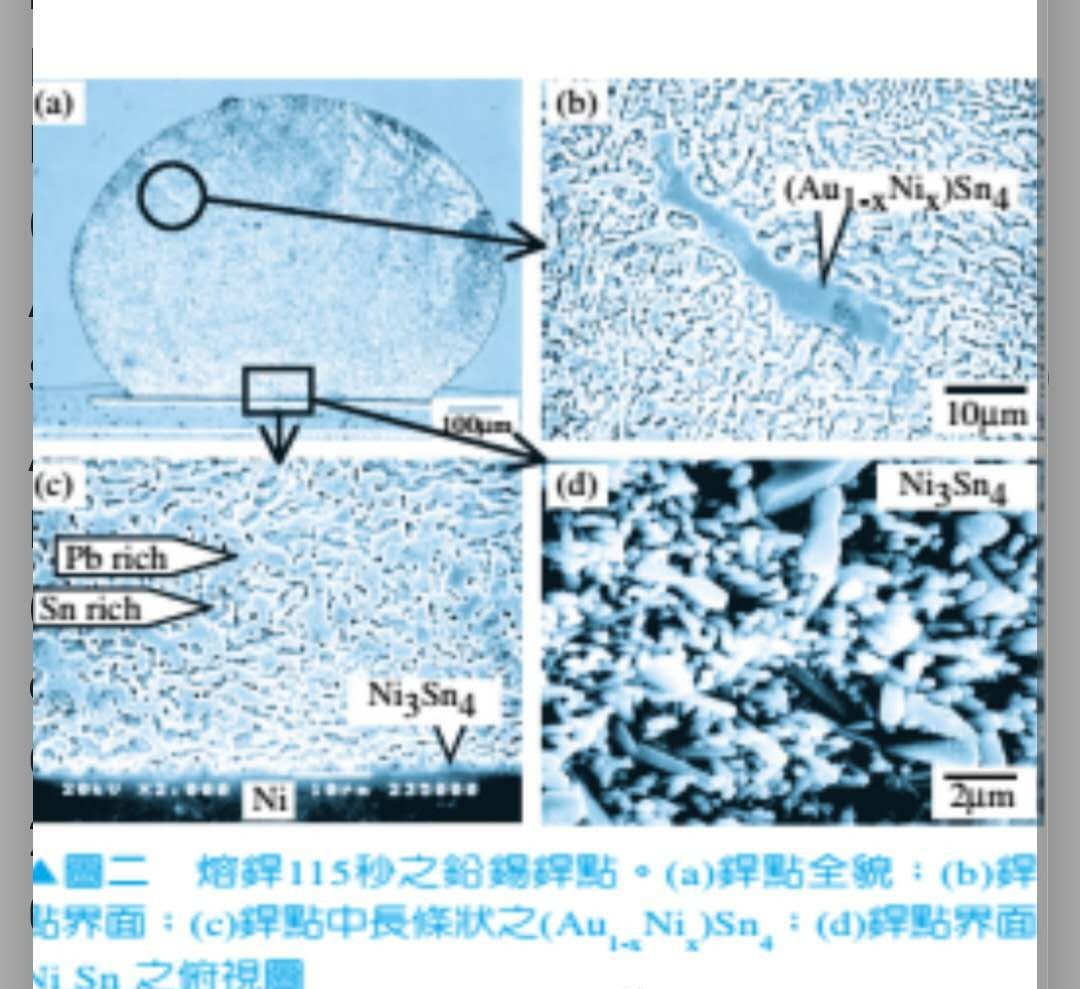

Zhao Libo: The coating itself contains gold, which disappears after welding. The surface of the coating is made of gold and nickel. This is normal, as shown below:

george tsao: If the needle used to apply EDS has been welded, then the EDS will be in vain. You need to take a new needle without welding it @赵立博

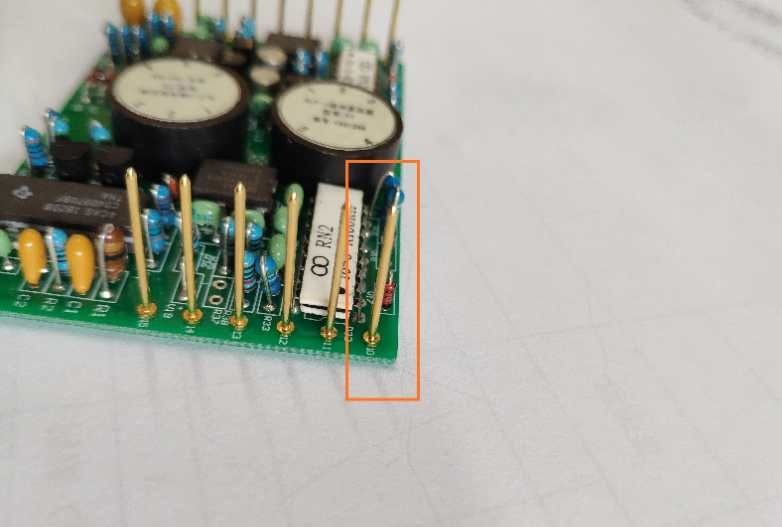

Zhao Libo: I put three needles in to make the injection, two of them fell off after welding, and one is new @george tsao

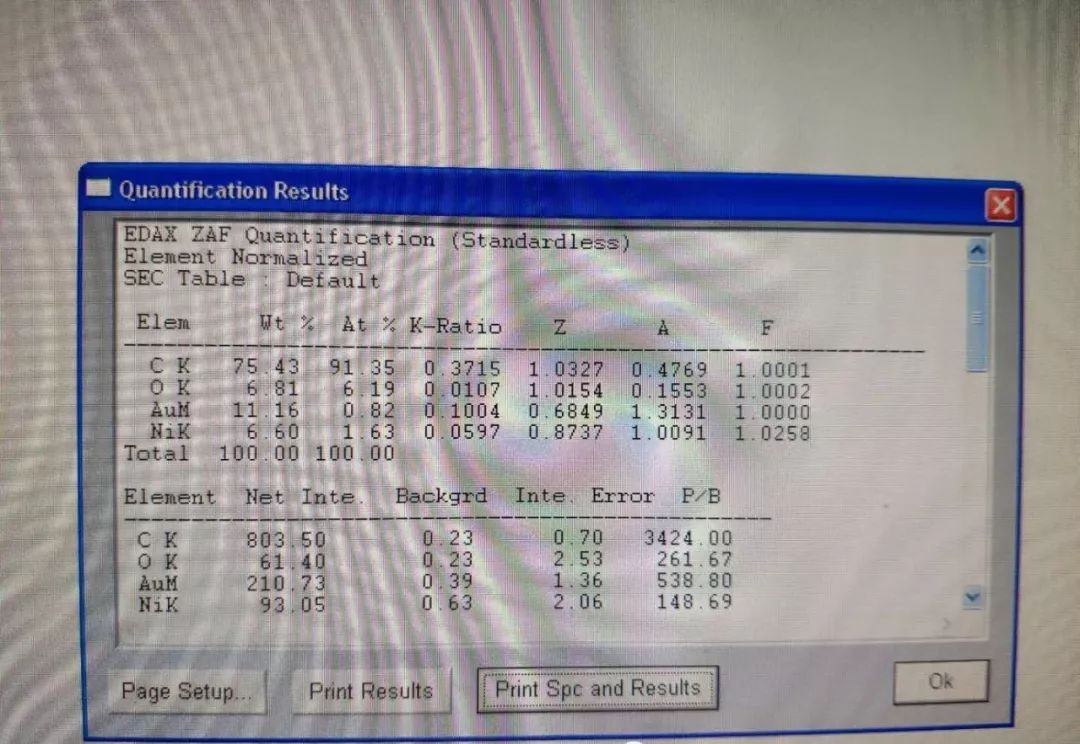

george tsao: The latter so-called normal one is not normal if it is brand new, so there is a problem. The AU is only 11.6 and the protective effect is completely lost.

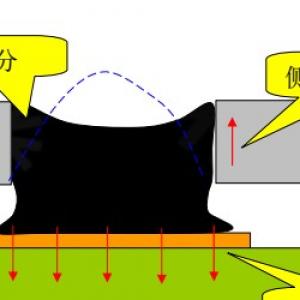

Liao Xiaobo: In other words, the interface where the gold needle fell off occurred on one side of the gold needle, and the analysis and test results on this side did not find gold, tin, or lead, indicating that it was a virtual solder (cold solder) at the beginning @ Zhao Libo

Zhao Libo: Yes, the shedding interface is on the side of the gold needle, and no gold, tin, or lead was found@Liao Xiaobo

HAWK: eds analysis is a rough result. It is recommended to mount the sample after slicing and conduct precise analysis. It doesn’t make any sense if you put the whole needle in like this @ Zhao Libo

Zhao Libo: The 11.6 I posted just now is because it is suspected that there is contamination on the surface of the test point. It contains 75% carbon. This carbon should be organic matter. It is suspected that it is residual material from machining. There is also a point that shows sodium and potassium. That point There should be sweat residue @george tsao

george tsao: that's the question, look at it with a microscope, look at it more. Everything else is a minor issue

Zhao Libo: This situation can definitely be caused by cold sweat rather than golden crisp, right?

george tsao: is this new? Or did it fall off after welding? @zhao libo

Zhao Libo: It fell off

george tsao: Of course you can’t see the gold after it falls off, Au

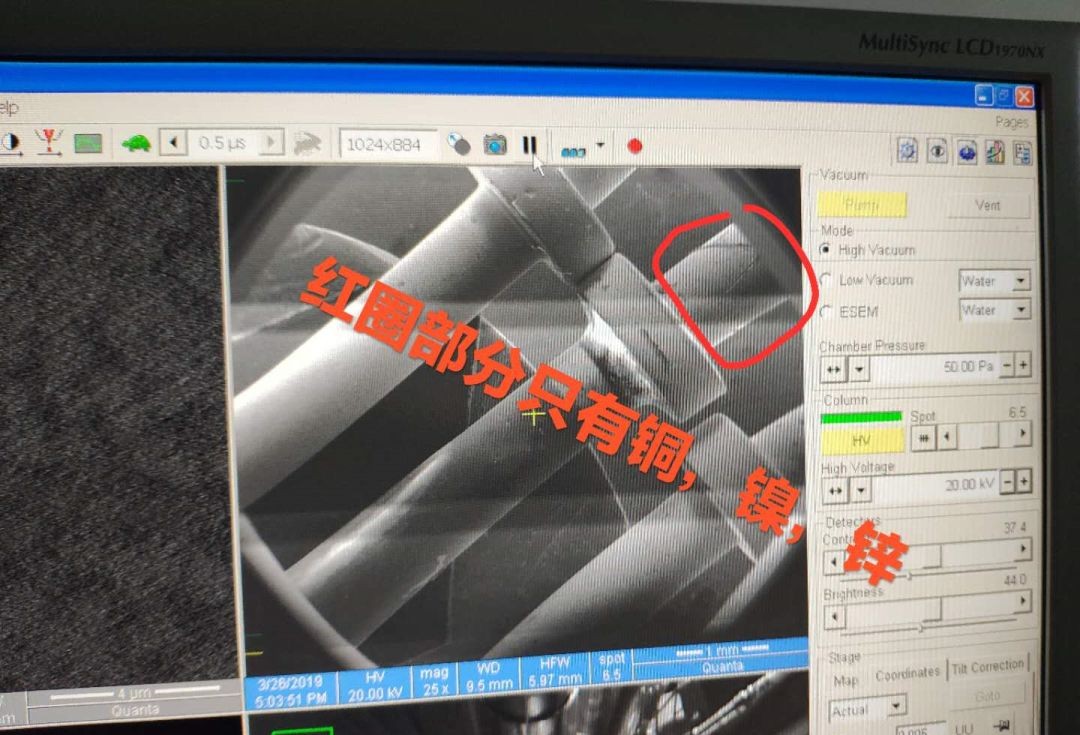

Zhao Libo: There is no tin or lead. If it is gold brittle, what will be the result? @george tsao

george tsao: If you don’t eat tin, where does the tin and lead come from? If it is a gold brittle part, you can see some of the tin and IMC that are peeling off. It seems that there is no @ Zhao Libo

Zhao Libo: Is it similar to the picture below?

george tsao: similar, but this is a very poor condition and will almost certainly produce golden brittleness